Locating the perfect grease fittings suitable for your needs can often be more challenging than anticipated. This complexity arises from the broad range of variations they display, including differing types, sizes, and unique functionalities.

Although grease fittings are fundamental to proper machine lubrication, harm and damage could ensue if they are misused. Spotting the most suitable grease fitting may seem like a challenging task but take it easy!

With this article, you will learn how to identify grease fittings and navigate your grease fittings selection properly. So, let’s dive in and find the right parts for you!

Grease fitting basics

NEIKO 50463A Grease Fitting Assortment

CO-Z 150pc Grease Fitting Kit

Functions

A grease fitting, sometimes called a Zerk fitting, grease nipple, or Alemite fitting is a small metal fixture used on mechanical assemblies. It provides lubrication to internal parts without leaks or overspill. Adding lubricants to mechanical systems helps improve their efficiency.

The grease fittings remain closed until the pressure from the grease gun opens them to dispense grease into the system’s moving parts, greatly reducing the possibilities of machinery failure.

Design

Grease fittings are set in place by a threaded connection. Inside the fitting, a small captive bearing ball is pushed against a retaining spring by the grease gun’s pressure.

The setup operates as a pathway that allows the grease to flow to the bearing. When the pressure releases, the bearing ball returns to the tip.

The bearing ball blocks dirt and other wastes from entering the bearing. It also acts as a check valve that creates a seal, obstructing the grease from flowing back out of the fitting.

Grease fittings are attached to a grease gun to administer a pressure-resistant connection. Also, they have a channel behind the opening that runs straight to the area where you need to grease.

Material

Most grease fittings are made of zinc-plated steel, stainless steel, carbon steel, mild steel, or brass. Some variations also have a supplemental coating of chromate to limit corrosion and improve durability.

Grease fitting thread identification

Types of grease fitting threads

There are many types of grease fitting threads available for use. But how can you be certain about the functionality of your grease fitting thread assembly? Let’s learn how to identify common thread types and how to choose the best for your application!

Threads are the ridges that wrap around the cylinder or cone and form a coil. There are six common different types of threads:

+ BSPP (British Standard Pipe Parallel)

+ BSPT (British Standard Pipe Taper)

+ Metric parallel

+ Metric tapered

+ NPT/NPTF (National Pipe Thread/National Pipe Thread Fuel)

+ UN/UNF (United/United Fine)

How to identify grease fitting thread

Keeping track of the six commonly used types of threads is not a simple task. It’s easy to select an incorrect part accidentally, but the following text offers a few ways to get to the correct choice. Here are some ways to identify the threads on your grease fittings:

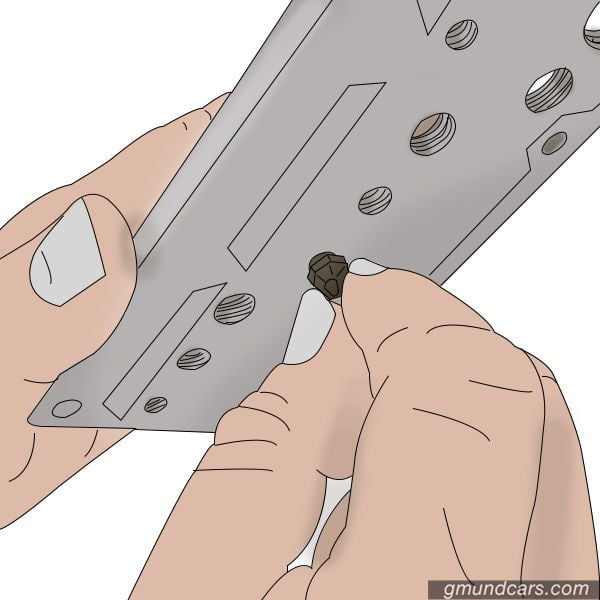

With a grease fitting gauge

Using a specific tool called grease fitting thread gauge is the easiest method to determine the thread on a grease fitting.

This special tool helps save time and grants a simple way to distinguish one grease fitting thread from another. It includes the standard metric sizes such as the UNF, the American standard, the British standard, and many more.

Without a grease fitting gauge

Although having a grease fitting thread gauge is convenient, you can still identify the correct grease fitting thread through various ways without needing this tool.

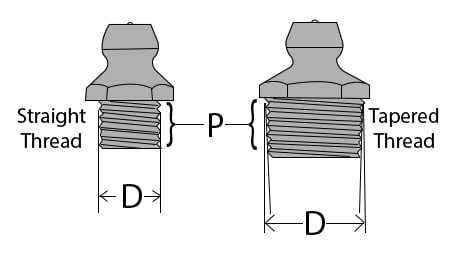

Parallel vs. Tapered

To determine if the thread is parallel or tapered, focus on its diameter. If the thread’s diameter runs straight from top to bottom, the thread is parallel. But if the thread’s diameter gets narrower towards the bottom, the thread is tapered.

| Parallel Threads | Tapered Threads |

|---|---|

| BSPP | BSPP |

| Metric parallel | Metric parallel |

| UN/UNF | NPT/NPTF |

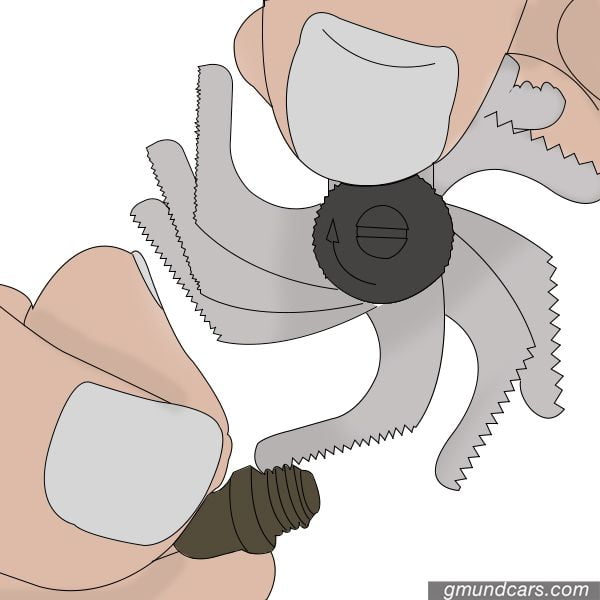

Thread pitch

The thread pitch is the number of threads per inch. A pitch gauge measures the distance between the individual crests or the pitch of a thread, and it is the optimal way to compare the numerous threads.

| Thread Type | Pitch Size |

|---|---|

| BSPP | 11, 14, 19, 28 |

| BSPT | 11, 14, 19, 28 |

| Metric parallel | 1.0, 1.5, 2.0 |

| Metric tapered | 1.0, 1.5, 2.0 |

| NPT/NPTF | 11½, 14, 18, 27 |

| UN/UNF | 12, 14, 16, 18, 20, 24 |

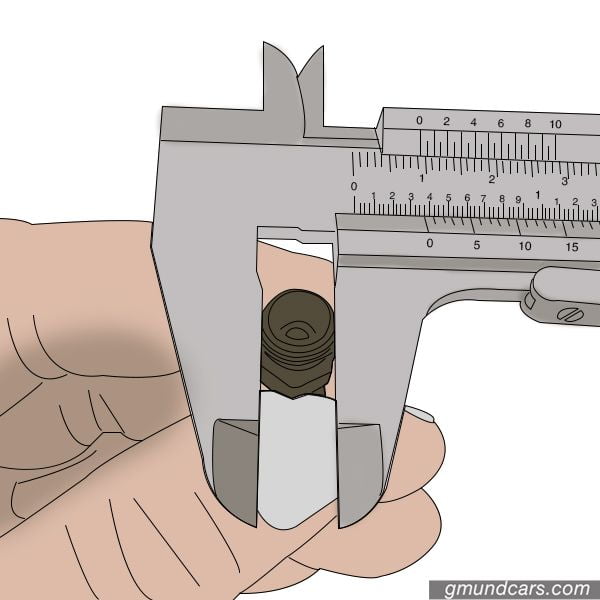

Thread diameter

A caliper tool is handy for measuring the thread diameter of your grease fitting. In addition, it is a simple two-part tool that can measure the internal and external diameters of objects.

Use the lower jaw of your calliper to measure the external diameter of your grease fitting. The diameter of your grease fitting would be the point where the 0 (zero) mark of your calliper’s slider is pointed at.

Types and sizes of grease fittings

Learning the different types and sizes of grease fittings is an important step, but it will be a little confusing. In this breakdown, we will introduce you to various grease fittings that provide the world with a quick and functional greasing procedure. Let’s explore some of the grease fitting assortments.

NEIKO 50463A Grease Fitting Assortment

CO-Z 150pc Grease Fitting Kit

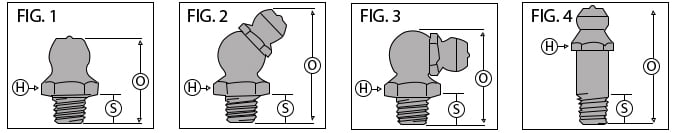

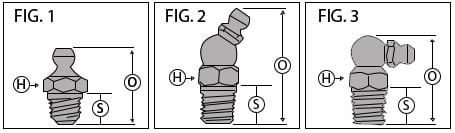

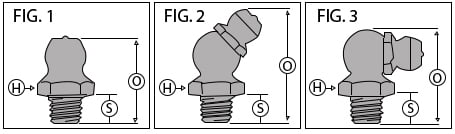

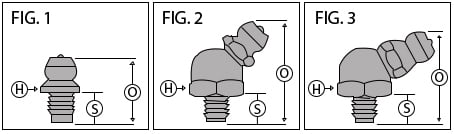

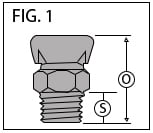

1/4”- 28 taper thread fittings

¼”-28 taper thread fittings are usually zinc-plated. They are suitable for use in automobiles and other kinds of commercial machinery. Some of its features include a dirt-repellent ball check and a maximum pressure range of 10,000 psi.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

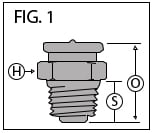

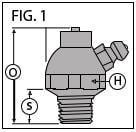

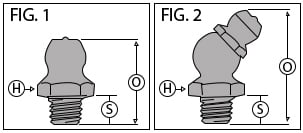

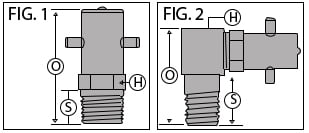

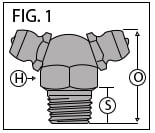

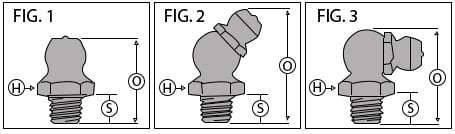

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (A) | Shank Length (S) | Hex Size (H) |

| 1637-B1 | 5210 | H-145 | 1/4"-28 SAE 45 degree | 45° | 1/4"-28 Taper (SAE-LT) | 2 | 27/32" | 7/32" | 3/8" |

| 1641-B | 5010 | H-100 | 1/4"-28 SAE straight | Straight | 1/4"-28 Taper (SAE-LT) | 1 | 35/64" | 3/16" | 5/16" |

| 1652-B | 5013 | H-100-RLA | 1/4"-28 SAE long thread | Straight | 1/4"-28 Taper (SAE-LT) | 4 | 11/16" | 23/64" | 5/16" |

| 1680-B | 5014 | H-100-LMA | 1/4"-28 SAE medium long | Straight | 1/4"-28 Taper (SAE-LT) | 4 | 31/32" | 5/8" | 5/16" |

| 1698-B | 5017 | H-100-LA | 1/4"-28 SAE long | Straight | 1/4"-28 Taper (SAE-LT) | 4 | 1-1/8" | 25/32" | 5/16" |

| 1911-B1 | 5410 | H-190-A | 1/4"-28 SAE 90 degree | 90° | 1/4"-28 Taper (SAE-LT) | 3 | 3/4" | 7/32" | 3/8" |

| 3010-B1 | 700396 | H-165-RL | 1/4"-28 65° long thread | 65° | 1/4"-28 Taper (SAE-LT) | 2 | 13/16" | 19/64" | 3/8" |

| 3014-B | N/A | H-100-LLA | 1/4"-28 straight very long | Straight | 1/4"-28 Taper (SAE-LT) | 4 | 1-5/8" | 1" | 5/16" |

| N/A | 5311 | H-165 | 1/4"-28 SAE 65 degree | 60° | 1/4"-28 Taper (SAE-LT) | 2 | 3/4" | 7/32" | 3/8" |

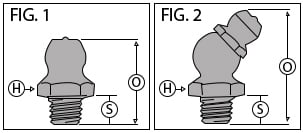

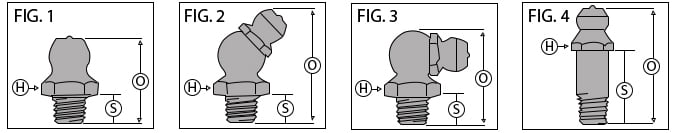

1/4”- 28 straight thread fittings

¼”-28 straight thread fittings are zinc-plated fittings frequently used in cars and a range of industrial equipment.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 333330 | N/A | H-100-28-LA | 1/4"-28 UNF-2A straight | Straight | 1/4"-28 UNF-2A | 1 | 17/32" | 3/16" | 17/32" |

| 369609 | N/A | H-100-28-C | 1/4"-28 UNF-2A straight | Straight | 1/4"-28 UNF-2A | 1 | 7/16" | 1/8" | 5/16" |

| 1770-B1 | N/A | H-145-CU | 1/4"-28 UNF-2A 45 degree | 45° | 1/4"-28 UNF-2A | 2 | 41/64" | 1/8" | 3/8" |

| 1792-B | 5527 | H-100-28 | 1/4"-28 UNF-2A straight | Straight | 1/4"-28 UNF-2A | 1 | 33/64" | 5/32" | 9/32" |

Metric grease fittings

Metric grease fittings sometimes called metric hydraulic fittings and metric zerks can take the pressure up to 10,000 psi. Their material is often regular and stainless steel. You can find this type of fitting in industrial machinery, rugged automotive, and agricultural applications.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 2109 | 5181 | M10-1-AM | 10mm x 1mm / straight | Straight | 10mm x 1mm | 1 | 15.2mm | 5.9mm | 11mm |

| 2110 | 5182 | M10-45-AM | 10mm x 1mm / 45 degree | 45° | 10mm x 1mm | 2 | 23.5mm | 5.5mm | 11mm |

| 2111 | 5183 | M10-90-AM | 10mm x 1mm / 90 degree | 90° | 10mm x 1mm | 3 | 19.0mm | 5.5mm | 11mm |

| 2106 | 5175 | M6-1-AM | 6mm x 1mm / straight | Straight | 6mm x 1mm | 1 | 13.5mm | 4.6mm | 7mm |

| 2107 | 5176 | M6-45-AM | 6mm x 1mm / 45 degree | 45° | 6mm x 1mm | 2 | 22.6mm | 5.5mm | 9mm |

| 2108 | 5177 | M6-90-AM | 6mm x 1mm / 90 degree | 90° | 6mm x 1mm | 3 | 18.0mm | 5.5mm | 9mm |

| 2103 | 5178 | M8-1-AM | 8mm x 1mm / straight | Straight | 8mm x 1mm | 1 | 14.7mm | 5.6mm | 9mm |

| 2104 | 5179 | M8-45-AM | 8mm x 1mm / 45 degree | Straight | 8mm x 1mm | 2 | 14.9mm | 5.8mm | 9mm |

| 2105 | 5180 | M8-90-AM | 8mm x 1mm / 90 degree | 90° | 8mm x 1mm | 3 | 17.8mm | 5.5mm | 9mm |

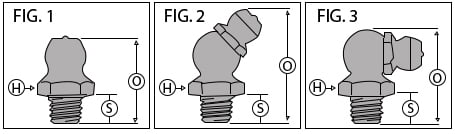

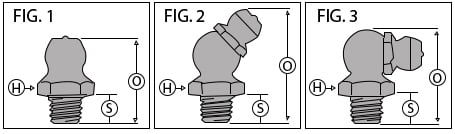

Flush type grease fittings

Flush type grease fittings are suited for machines where protruding fittings cannot be equipped, such as pulleys, shafts, and other rotating bearings. Flush fittings are not susceptible to erosion since they don’t protrude from the surface like other fittings.

|

||||||||

|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall length (O) | Shank length (S) |

| 1452 | N/A | AH-18FLMA | 1/8"-NPTF Slotted Thread | Slotted | 1/8"-NPTF | 2 | 17/32" | N/A |

| 1814 | N/A | AK-516F | 5/16" Drive, no thread | Straight | Drive (No Thread) | 7 | 21/64" | 9/32" |

| 1815 | N/A | AH-18F | 1/8"-NPTF Slotted Thread | Slotted | 1/8" NPTF | 1 | 23/64" | 19/64" |

| 1851 | 700392 | AH-1428FJ | 1/4"-28 U.N.F | 1/4"-28 U.N.F | 10-32 U.N.F | 4 | 13/32" | 19/64" |

| 1877 | 700397 | AK-18FC | 1/8" Drive, Slotted Thread | Straight | Drive (No Thread) | 6 | 11/64" | 1/8" |

| 1885 | 700502 | AK-14-FJ-1 | 1/4" Drive, Slotted Thread | Straight | Drive (No Thread) | 7 | 9/32" | 15/64" |

| 3036 | N/A | AH-316F | 3/16"-Drive | Straight | Drive | 6 | 3/8" | 5/16" |

| N/A | 700502A | AH-1032FJ | 10-32 U.N.F Slotted Thread | Straight | 10-32 U.N.F | N/A | 11/32" | 15/64" |

| Z741-A | N/A | AH-14F | 1/4"-NPTF Slotted Thread | Slotted | 1/4"-NPTF | 3 | 9/16" | N/A |

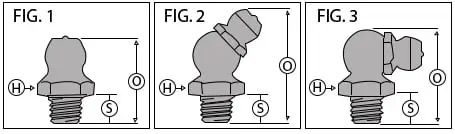

Button head grease fittings

Button head grease fittings can be for strenuous applications such as heavy machinery and high-powered equipment. They are appropriate for delivering high amounts of lubrication for smooth and fluid work.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 1823 | N/A | H-300-CBG | 1/4"-NPTF | Straight (Giant) | 1/4"-NPTF | 1 | 1-9/32" | 35/64" | 7/8" |

| 1831 | N/A | H-200-CBG | 1/8"-NPTF | Straight (Giant) | 1/8"-NPTF | 1 | 1-3/16" | 29/64" | 7/8" |

| 1820-1 | N/A | H-500-CBG-SS | 1/2"-NPTF (STAINLESS) | Straight (Giant) | 1/2"-NPTF | 1 | 1-1/16" | 1/2" | 7/8" |

| 1822-A1 | N/A | H-400-CBG | 3/8"-18 NPTF | Straight (Giant) | 3/8"-18 NPTF | 1 | 1-5/16" | 9/16" | 7/8" |

| A1184 | 5700/5701 | H-200-CB | 1/8"-NPTF | Straight | 1/8"-NPTF | 1 | 3/4" | 23/64" | 5/8" |

| A1186 | 5706 | H-300-CB | 1/4"-NPTF | Straight | 1/4"-NPTF | 1 | 27/32" | 7/16" | 5/8" |

| A1188 | 5711 | H-400-CB | 3/8"-NPTF | Straight | 3/8"-NPTF | 1 | 1-1/16" | 37/64" | 3/4" |

| A1190 | N/A | H-500-CB | 1/2"-NPTF | Straight | 1/2"-NPTF | 1 | 1-1/16" | 35/64" | 7/8" |

| C-69 | N/A | H-200-CBRI | 1/8"-NPTF FEMALE | Straight | 1/8"-NPTF | 1 | 31/32" | 13/32" | 5/8" |

| M1184 | N/A | H-200-CB-MON. | 1/8"-PTF (MONEL) | Straight | 1/8"-PTF | 1 | 3/4" | 11/32" | 5/8" |

Hydraulic shut-off grease fittings

Hydraulic shut-off fittings are often suitable for bearing seals in water pumps. These fittings shut off at certain pressure levels, therefore restricting over-greasing and over-pressurization of the bearing seals.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | SAE # | Descriptions | Type | Thread | FIG. | Overall length (O) | Shank length (S) | Hex size (D) | Shut-off Pressure (psi) |

| 1795-B | H-260-SO2 | 1/8" PTF / 60° Angle | 60° | 1/8" PTF | 1 | 1" | 17/64" | 5/8" | 5-20 lb |

| 1940-B | H-260-SO1 | 1/8" PTF / 60° Angle | 60° | 1/8" PTF | 1 | 1" | 17/64" | 5/8" | 60-110 lb |

Special thread grease fittings

Special thread grease fittings are special threads and sizes for specific greasing usage. They are suited for matching corresponding straight threads. Moreover, most of them include a high-pressure ball check and you can customize the special threads to fit almost any use.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 3016 | N/A | H-1032 | 10-32 UNF-2A straight | Straight | 10-32 UNF-2A | 1 | 1/2" | 1/8" | 1/4" |

| 3018 | N/A | H-640 | 6-40 UNF-2A straight | Straight | 6-40 UNF-2A | 1 | 1/2" | 9/64" | 1/4" |

| 1631-B | N/A | H-51632 | 5/16"-32 UNEF-2A straight | Straight | 5/16"-32 UNEF-2A | 1 | 21/32" | 7/32" | 3/8" |

| 1648-B1 | N/A | H-5163265 | 5/16"-32 UNEF-2A, 65 degree | 65° | UNEF-2A | 2 | 51/64" | 7/32" | 3/8" |

| 1711-B | 5061 | H-51624 | 5/16"-24 UNF-2A straight | Straight | 5/16"-24 UNF-2A | 1 | 21/32" | 1/4" | 3/8" |

Pin type grease fittings

Pin type grease fittings include a cross pin that creates a lock to allow no room for leaks. Pin type grease fittings were one of the first zerks developed and still being used in automobiles today.

|

||||||||

|---|---|---|---|---|---|---|---|---|

| Alemite # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| A336 | H-200-PIN-B | 1/8" PTF / str. (brass body / steel pin & ball) | Straight | 1/8" PTF | 1 | 31/32" | 17/64" | 7/16" |

| A358 | H-290-PIN-B | 1/8" PTF / 90 degree (brass) | 90° | 1/8" PTF | 2 | 1-1/16" | 17/64" | 1/2" |

| A359 | H-300-PIN-B | 1/4" NPTF / straight (brass) | Straight | 1/4" NPTF | 1 | 11/32" | 17/64" | 17/32" |

| A361 | H-390-PIN-N | 1/4" NPTF / 90 deg. (steel/ nickle) | 90° | 1/4" NPTF | 2 | 1-5/16" | 3/5" | 9/16" |

| A684 | H-245-PIN-B | 1/8" PTF / 45 degree (brass) | 45° | 1/8" PTF | N/A | 1-1/2" | 5/16" | 1-9/16" |

| M336 | H-200-PIN-M | 1/8" PTF / str. (brass body / brass pin & ball) | Straight | 1/8" PTF | 1 | 31/32" | 17/64" | 7/16" |

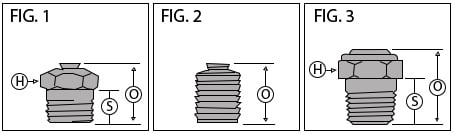

Leakproof grease fittings

Leakproof grease fittings prevent lubricant leaks and keep external particles from entering the channel. Besides, this type of fitting is suitable for operations where having firm seals is critical, like in the food and textile industries. A dust cap is a recommended accessory.

|

||||||||

|---|---|---|---|---|---|---|---|---|

| Alemite # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 1634 | H-200-1634 | 1/8"-PTF | Straight | 1/8" NPT | 1 | 27/32" | 23/64" | 7/16" |

| 1650 | H-200-LP | 1/8"-NPT | Straight | 1/8" NPT | 1 | 29/32" | 25/64" | 7/16" |

| 1692 | H-230-LP | 1/8"-NPT 30 degree | 30° | 1/8" NPT | 2 | 1-7/32" | 25/64" | 7/16" |

| 1693 | H-290-LP | 1/8"-NPT 90 degree | 90° | 1/8" NPT | 3 | 31/32" | 25/64" | 7/16" |

| 369533 | CONE-LP | 7/16" round, no thread | Straight | 7/16" Round | 1 | 55/64" | N/A | 7/16" |

| 369619 | H-100-LP | 1/4"-28 taper thread | Straight | 1/4"-28 Taper | 1 | 37/64" | 5/16" | 7/16" |

| 1634-B | H-200-1634-B | 1/8"-PTF, surface ball ck | Straight | 1/8" NPT | 1 | 1" | 33/64" | 7/16" |

1/8” PTF grease fittings

1/8” PTF grease fittings fit in industrial equipment and heavy machinery. They include a zinc coating and a special dust-proof cap.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 1649 | N/A | H-265-LLA | 1/8"-PTF 65° very long | 65° | 1/8" PTF SAE Special Short | 2 | 2-3/4" | 2-1/4" | 3/8" |

| 1958 | N/A | H-200-DR | 1/8"-PTF str. dustproof | Straight | 1/8" PTF SAE Special Extra Short | N/A | 1" | 5/16" | 7/16" |

| 1606-B | N/A | H-290-LMA | 1/8"-PTF 90 medium long | 90° | 1/8" PTF SAE Special Short | 3 | 1-1/4" | 1-1/4" | 7/16" |

| 1607-B | 5003 | H-200-LM | 1/8"-PTF medium long | Straight | 1/8" PTF SAE Special Short | 4 | 1-1/4" | 25/32" | 7/16" |

| 1610-BL | 5000 | H-200 | 1/8"-PTF straight | Straight | 1/8" PTF SAE Special Extra Short | 1 | 11/16" | 19/64" | 7/16" |

| 1611-B | 6004 | H-230 | 1/8"-PTF 30 degree | 30° | 1/8" PTF SAE Special Short | 2 | 15/16" | 19/64" | 7/16" |

| 1612-B | 5300 | H-265-A | 1/8"-PTF 65 degree | 65° | 1/8" PTF SAE Special Short | 2 | 27/32" | 19/64" | 7/16" |

| 1613-B | 5400 | H-290 | 1/8"-PTF 90 degree | 90° | 1/8" PTF SAE Special Short | 3 | 53/64" | 19/64" | 7/16" |

| 1618-B | 5505 | H-200-RI | 1/8"- NPTF internal thread | Straight | 1/8" NPT Female | N/A | 1" | 5/16" | 1/2" |

| 1620-B | N/A | H-245-RI | 1/8"-NPTF 45° female thrd | 45° | 1/8" PTF SAE Special Short | N/A | 1-1/8" | 13/32" | 7/16" |

| 1623-B | N/A | H-265-LM | 1/8"-PTF 65° med. long | 65° | 1/8" PTF SAE Special Short | 2 | 1-7/32" | 9/16" | 7/16" |

| 1638-B | 5200 | H-230-LMA | 1/8"-PTF 30° med. long | 30° | 1/8" PTF SAE Special Short | 2 | 2" | 1-1/4" | 7/16" |

| 1644-B | N/A | H-200-C | 1/8"-PTF straight short | Straight | 1/8" PTF SAE Special Extra Short | 1 | 9/16" | 15/64" | 7/16" |

| 1669-B | 5007 | H-200-LA | 1/8"-PTF long | Straight | 1/8" PTF SAE Special Short | 4 | 1-3/4" | 1-15/64" | 7/16" |

| 1684-B | 5009 | H-200-LLA | 1/8"-PTF very long | Straight | 1/8" PTF SAE Special Short | 4 | 2-5/8" | 2-1/32" | 7/16" |

| 1688-B | 5200 | H-245 | 1/8"-PTF 45 degree | 45° | 1/8" PTF SAE Special Short | 2 | 27/32" | 19/64" | 7/16" |

1/4″ PTF grease fittings

¼” PTF grease fittings are extensively used in hefty machinery with bigger bearings with heavy lubricant supplication and for cold weather operations.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Description | Type | Thread | FIG. | Overall length (O) | Shank length (S) | Hex size (H) |

| 1629-C | N/A | H-390 | 1/4"-PTF 90 DEGREE | 90° | 1/4"-PTF | 3 | 15/16" | 3/8" | 9/16" |

| 1629-B | 5350 | H-365 | 1/4"-PTF 65 DEGREE | 65° | 1/4"-PTF | 2 | 1-1/16" | 3/8" | 9/16" |

| 1627-B | 5050 | H-300 | 1/4"-PTF | Straight | 1/4"-PTF | 1 | 7/8" | 27/64" | 9/16" |

Pressure relief grease fittings

Pressure relief fittings function as relief vents releasing pressure building up in bearing housings or gearboxes. An internal valve opens and releases pressurized air.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 47100 | N/A | H-200-47100 | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 1/2" | 19/64" | 7/16" |

| 47200 | N/A | H-200-47200 | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 1/2" | 19/64" | 7/16" |

| 47640 | N/A | H-200-47640 | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 1/2" | 19/64" | 7/16" |

| 50500 | N/A | H-200-50500 | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 1/2" | 19/64" | 7/16" |

| 317400 | N/A | H-200-317400 | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 1/2" | 19/64" | 7/16" |

| 321839 | N/A | K-38-321839 | 3/8" DRIVE. | Straight | 1/8" PTF SAE Spl Short | 2 | 1/2" | N/A | N/A |

| 323060 | N/A | H-200-323060 | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 1/2" | 19/64" | 7/16" |

| 338382 | N/A | H-200-338382 | 1/8"-PTF. LEAKPROOF | Straight | 1/8" PTF SAE Spl Short | 3 | 9/16" | 11/32" | 7/16" |

| N/A | 5677 | H-200-5677 | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 1/2" | 19/64" | 7/16" |

| N/A | 5678 | H-200-5678J | 1/8"-PTF. | Straight | 1/8" PTF SAE Spl Short | 1 | 12.7 | 7.1 | 7/16" |

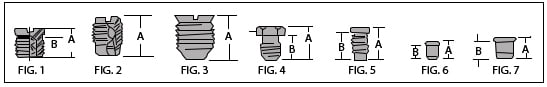

Thread forming grease fittings

Thread forming fittings, also called spin drive fittings, have hardened threads for insertion into holes with no threads. Besides reducing costs, inserting thread forming fittings into unthreaded holes provide a stronger grip. Thread forming fittings are great for high-pressure oil applicators. You can use them for industrial machinery and heavy equipment.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (A) | Shank Length (B) | Hex Size (D) |

| 3038-B | 205010 | H-100-GM | 1/4"-28 straight | Straight | 1/4"-28 Spl. Taper | 1 | 9/16" | 13/64" | 5/16" |

| 369582 | N/A | H-100-C-GM | 1/4"-28 straight short | Straight | 1/4"-28 Spl. Taper | 1 | 0.51 | 0.12 | 9/32" |

| 369584 | N/A | H-100-LMA-GM | 1/4"-28, straight med. long | Straight | 1/4"-28 Spl. Taper | 1 | 0.97 | 0.21 | 5/16" |

| 328435 | 700337 | H-100-GMPL | 1/4"-28 plug | Straight | 1/4"-28 Spl. Taper | 1 | 5/16" | 3/16" | 9/32" |

| 3053-B | 205210 | H-145-GM | 1/4"-28 45 degree | 45° | 1/4"-28 Spl. Taper | 2 | 13/16" | 3/16" | 3/8" |

| 3054-B | 205410 | H-190-GM | 1/4"-28 90 degree | 90° | 1/4"-28 Spl. Taper | 3 | 23/32" | 13/64" | 3/8" |

| 1720-B | 205000 | H-200-GM | 1/8" PTF straight | Straight | 1/4"-28 Spl. Taper | 1 | 5/8" | 1/4" | 7/16" |

| 369579 | N/A | H-200-LMA-GM | 1/8" PTF straight med. long | Straight | 1/4"-28 Spl. Taper | 1 | 0.68 | 0.21 | 7/16" |

| 1724-B | 5300 | H-245-GM | 1/8" PTF 45 degree | 45° | 1/4"-28 Spl. Taper | 2 | 27/32" | 13/64" | 7/16" |

| 1722-B | N/A | H-265-GM | 1/8" PTF 65 degree | 65° | 1/4"-28 Spl. Taper | 2 | 3/4" | 13/64" | 7/16" |

| 1723-B | 205400 | H-290-GM | 1/8" PTF 90 degree | 90° | 1/4"-28 Spl. Taper | 3 | 3/4" | 13/64" | 7/16" |

Drive type grease fittings

Drive type grease fittings also referred to as push-in grease fittings, are perfect for low or moderate pressure operations. They have serrated shanks for a strong grip.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (B) | Hex Size (H) |

| 1633 | 5026 | K-316-SBA | 3/16"- drive, no ball | Straight | 3/16" Drive | 1 | 5/8" | 1/4" | 5/16" |

| 1666 | 5036 | K-38-SBA | 3/8"- drive, no ball | Straight | 3/8" Drive | 1 | 37/64" | 7/32" | 7/16" |

| 1699 | 5030 | K-516-SBA | 5/16"- drive, no ball | Straight | 5/16" Drive | 1 | 5/8" | 7/32" | 3/8" |

| 1736 | N/A | K-18-SBA | 1/8"- drive, no ball check | Straight | 1/8" Drive | 1 | 9/16" | 1/4" | 5/16" |

| 1744 | 5318 | K-14-65-N | 1/4"- drive 65 degree | Straight | 1/4" Drive | 3 | 49/64" | 9/32" | 1/4" |

| 1952 | 700313 | K-14-CCSBA | 1/4"- EXT. short, no ball | Straight | 1/4" Drive | 1 | 15/32" | 1/8" | 11/32" |

| 3005 | 700375 | K-316-MSBA | 3/16"- med. short, no ball | Straight | 3/16" Drive | 1 | .468" | .172" | 5/16" |

| 3006 | N/A | K-316-CSBA | 3/16"- drive short, no ball | Straight | 3/16" Drive | 1 | .484" | .219" | 9/32" |

| 3009 | N/A | K-316-CCSBA | 3/16"- extra short, no ball | Straight | 3/16" Drive | 1 | .390" | .105" | 5/16" |

| 3019 | N/A | K-18-CSBA | 1/8"- drive short, no ball | Straight | 1/8" Drive | 1 | 15/32" | 5/32" | 5/16" |

| 321381 | 5044 | K-14-SBA | 1/4"- drive, no ball | Straight | 1/4" Drive | 1 | 35/64" | 1/4" | 11/32" |

| 1608-B | 5031 | K-516-N | 5/16"- drive | Straight | 5/16" Drive | 1 | 9/16'' | 17/64" | 3/8" |

| 1630-B1 | N/A | K-516-65-N | 5/16"- drive 65 degree | 65° | 5/16" Drive | 3 | 23/32" | 7/32" | 3/8" |

| 1646-B1 | 5385 | K-316-65-N | 3/16"- drive 65 degree | 60° | 3/16" Drive | 3 | 23/32" | 7/32" | 3/8" |

| 1728-B | 5033 | K-316-A | 3/16"- drive | Straight | 3/16" Drive | 1 | 33/64" | 1/4" | 5/16" |

| 1743-B | 5029 | K-14A | 1/4"- drive | Straight | 1/4" Drive | 1 | 35/64" | 1/4" | 5/16" |

| 1992-B1 | N/A | K-316-45-N | 3/16"- drive 45 degree | 45° | 3/16" Drive | 2 | 53/64" | 7/32" | 3/16" |

Monel grease fittings

Monel grease fittings are excellent at repelling wear and corrosion, especially in industrial settings. Monel fittings’ materials are from nickel or copper. For easy recognition, they feature a single notch on the hex. Because of its corrosion resistance, monel grease fittings are great for caustic environments. Moreover, some good examples of these environments are chemical factories or seaside ports.

|

||||||||

|---|---|---|---|---|---|---|---|---|

| Alemite # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 1921-B | H-230-MONEL | 1/8"-PTF 30 degree | 30° | 1/8" PTF | 2 | 1-1/4" | 11/32" | 7/16" |

| 1922-B | H-267-MONEL | 1/8"-PTF 67 1/2 degree | 67.5° | 1/8" PTF | 2 | 61/64" | 11/32" | 7/16" |

| 1966-B | H-100-MONEL | 1/4"-28 SAE straight | Straight | 1/4"-28 Taper | 1 | 17/32" | 3/16" | 5/16" |

| 1923-B | H-290-MONEL | 1/8"-PTF 90 degree | 90° | 1/8" PTF | 3 | 7/8" | 11/32" | 7/16" |

| 1961-B | H-200-MONEL | 1/8"-PTF straight | Straight | 1/8" PTF | 1 | 3/4" | 5/16" | 7/16" |

| 1962-B | H-200-C-MONEL | 1/8"-PTF str. short | Straight | 1/8" PTF | 1 | 5/8" | 9/32" | 7/16" |

| 1968-B | H-145-MONEL | 1/4"-28 SAE 45° | 45° | 1/4"-28 Taper | 2 | 13/16" | 13/64" | 5/8" |

| 1969-B | H-190-MONEL | 1/4"-28 SAE 90 degree | 90° | 1/4"-28 Taper | 3 | 3/4" | 13/64" | 3/8" |

Air vent grease fittings

Air vent grease fittings allow air to enter and exit while preventing dirt and other particles from infiltrating. You can use air vents on mechanical devices such as differentials, transmissions, and gearboxes.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Opening Pressure |

| 300805 | N/A | H-200-300805 | 1/8" PTF VENT | Straight | 1/8" PTF SAE Spl Short | 1 | 1 | 0.19 | Felt Filter |

| 301370 | 5698 | H-200-VENT | 1/8" PTF VENT | Straight | 1/8" PTF SAE Spl Short | 1 | 0.78 | 0.28 | N/A |

| 304810 | N/A | H-200-304810 | 1/8" PTF VENT | Straight | 1/8" PTF SAE Spl Short | 1 | 1 | 0.19 | 1-3" Water |

| 324970 | N/A | K-324970 | DRIVE VENT | Straight | Drive | 1 | 1 | 0.8 | 6-12" Water |

| 327240 | N/A | H-200-327240 | 1/8" PTF VENT | Straight | 1/8" PTF SAE Spl Short | 1 | 1 | 0.19 | 1 to 1-1/2 psi |

| 330766 | N/A | H-200-330766 | 1/8" PTF VENT | Straight | 1/8" PTF SAE Spl Short | 1 | 1 | 0.19 | 2-1/2 to 4 psi |

| 131000-T | N/A | H-200-131000-T | 1/8" PTF VENT | Straight | 1/8" PTF SAE Spl Short | 1 | 1 | 0.19 | 12" Water Max. |

Double head grease fittings

Double head fittings provide another head for doubling the lubricant supply. They include a ball check to keep out debris. Its two heads are great when you need to apply grease at two times the speed. It can also be used when two alternating or simultaneous greasing is necessary.

|

||||||||

|---|---|---|---|---|---|---|---|---|

| Alemite # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 369574 | H-270-DH | 1/8" PTF / 70 DEGREE | 70° | 1/8" PTF | 27/32" | 19/64" | 1/2" |

|

Stainless steel grease fittings

Stainless steel fittings are made from stainless steel, which is resilient to weathering and corrosion. Besides, stainless steel fittings can tolerate extreme temperatures. They feature two notches for easy recognition. The materials of stainless-steel fittings make them great for high corrosion environments such as seaside or chemical plants. It is also easier to clean thanks to its stainless body.

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alemite # | Lincoln # | SAE # | Descriptions | Type | Thread | FIG. | Overall Length (O) | Shank Length (S) | Hex Size (H) |

| 1921-S | N/A | H-230-SS-AM | 1/8"-PTF 30 degree | 30° | 1/8"-PTF | 2 | 1.25" | .34" | 7/16" |

| 1922-S | N/A | H-267-SS-AM | 1/8"-PTF 67 1/2 degree | 67° | 1/8"-PTF | 2 | .95" | .34" | 7/16" |

| 1923-S | N/A | H-290-SS-AM | 1/8"-PTF 90 degree | 90° | 1/8"-PTF | 3 | .82" | .27" | 7/16" |

| 1961-S | 5000-9 | H-200-SS-AM | 1/8"-PTF straight | Straight | 1/8"-PTF | 1 | .62" | .25" | 7/16" |

| 1966-S | 5010-9 | H-100-SS-AM | 1/4"-28 SAE straight | Straight | 1/4"-28 Taper Thread | 1 | .54" | .20" | 5/16" |

| 1968-S | 5210-9 | H-145-SS-AM | 1/4"-28 45 degree | 45° | 1/4"-28 Taper Thread | 2 | .88" | 0.2'' | 3/8" |

| 1969-S | 5410-9 | H-190-SS-AM | 1/4"-28 90 degree | 90° | 1/4"-28 Taper Thread | 3 | .69" | .20" | 3/8" |

| N/A | 5033-9 | K-316-SS-AM | 3/16"-DRIVE | Straight | 3/16" Drive | 4 | .50" | .21" | 5/16" |

Grease fittings tips

Before finding the right grease fitting, you must first determine what kind of grease fitting thread you will use. You can choose from several kinds of thread components available. The thread fittings are commonly used in the BSPP, BSPT, metric parallel, metric tapered, NPT/NPTF, and UN/UNF.

After determining your fitting thread, then you can now choose from the many different kinds of grease fittings, according to each of their particular features. There are also various types of grease guns to use alongside grease fittings, including the lever, pistol-grip, pneumatic, and cordless guns. Most of these guns are appropriate to use for any application.

More importantly, keeping your grease fitting in its tip-top shape will help maintain its effectiveness. Doing so will also help you save a ton of money in the long run. Here are some tips on how you can properly maintain your grease fitting.

- Use a clean rag to wipe your fitting before installing it. A lint-free cloth would be the best for this job.

- Regularly check your grease fittings and immediately replace any defective ones.

- As much as possible, use a common fitting type and size for similar applications.

- Use label tags to help you remember the type of grease the flows through each of your grease fittings.

- Know the delivery capacity of your grease fitting and make sure not to exceed them.

- Maintain your grease gun properly as well If you are using one. Avoid storing it in moist and dirty areas. Cover them with a thick cloth or store them inside a hard case if possible.

- Exercise extra caution and take safety measures when using your grease gun and grease fitting.

- After using your grease gun, always wipe down your fitting to avoid contamination of dirt and moisture.

FAQs

1. Why does my grease gun get stuck in the fitting?

The gun gets stuck in the fitting because it is clogged by debris or hardened grease. It would help if you clean grease fittings and grease guns before use to avoid the chances of dirt being brought inside the bearing. Make sure the fitting is free of dirt before locking the coupler to the zerk, and do not combine old grease with new grease.

2. What do I do if my grease fitting won’t take grease?

Inspect the following if the grease fitting won’t take grease: If the fitting nipple is damaged, replace the fitting. But if the fitting is not damaged, it is obscured by debris that prevents the flow, and you should replace the fitting. If there seems to be no damage, then use an impact fitting cleaner to break down the clogs with compressed fluid chemically.

3. How to remove the grease gun from zerk fitting?

Make sure to release the pressure on the fitting by tilting the coupler at an angle to break the seal or loosening it with a wrench. Besides, after releasing the pressure, remember to twist the coupler back and forth.

4. How to attach a grease gun to a zerk fitting?

First, make sure that the grease gun and the zerk are dirt-free before fastening the nozzle to the fitting. Then, angle the coupler to the fitting and press down. Secure the connection by tightening the nozzle on the fitting, and when the coupler clicks into place, start up the grease gun, and let the lubricant flow.

To sum up

Grease fittings offer us an easier way to keep machinery in good condition. However, we should also do our due diligence in finding the best ones for our needs. Therefore, you need to keep in mind the type of thread you need, your options, and correct their application.

We hope that this article has aided you through the grease fitting identification and selection process and finding the perfect grease fitting for your task! If you have any questions, leave us a comment now!