Don’t dismiss a winch just because it doesn’t include a solenoid. It should be noted that most winches produced in this day and age do not have a solenoid included. Before disregarding a winch you happen upon, you might find it advantageous to read this.

Wiring a winch without a solenoid is a little different than wiring a winch with it. For example, you will need to use longer wires, and your existing connectors may not be suitable. However, the basic principles remain the same.

In this article, we’re going to dive deep into wiring a winch without a solenoid and explain what the different wires do. You can skip all that tedious trial and error by reading this guide to learn the right way.

Why do you Bypass the Solenoid?

Easily Damaged

The main reason why you would want to bypass a solenoid, asides from not having one, is that they can get damaged easily. They have moving parts exposed to several elements, so they are prone to rusting and breaking down. If your solenoid breaks down, you will have no way of releasing your cable.

Defective Motor

You may notice that the motor stops working and it produces a “clicking” or “clacking” sound. This is usually because the battery connections are not clean and tight, you have a low or dead battery or a broken or damaged positive (red) battery cable.

These signs indicate that you may have a motor problem or a solenoid problem.

Testing the Winch Motor

You may also choose to test the winch motor by bypassing the solenoid.

Preparation Stage

Before you start working, keep the following safety considerations in mind:

- Study and understand the winch solenoid wiring diagram, which shows the motor’s design.

- Make sure that you disconnect your battery before making any changes to the product.

- Wear the appropriate clothing to avoid injury from moving parts. Wearing jewelry or clothing that is too loose is not a good idea because it may become entangled in those parts.

- When working with winch cable, wear leather gloves. You risk injuring yourself if you handle a broken wire with your bare hands.

Here’s what you need:

- A winch.

- Wire and terminals.

- A spade terminal block (It’s a terminal with a hole in it and screws to hold the wires in place).

- A fuse holder (Check the amperage of your wire, you need to match it for safety reasons).

- A fuse (Check the amperage of your wire, you need to match it for safety reasons).

- Two crimps on spade terminals (Much safer than soldering).

- Soldering gun, solder, and a lot of patience or a ton of wiretaps.

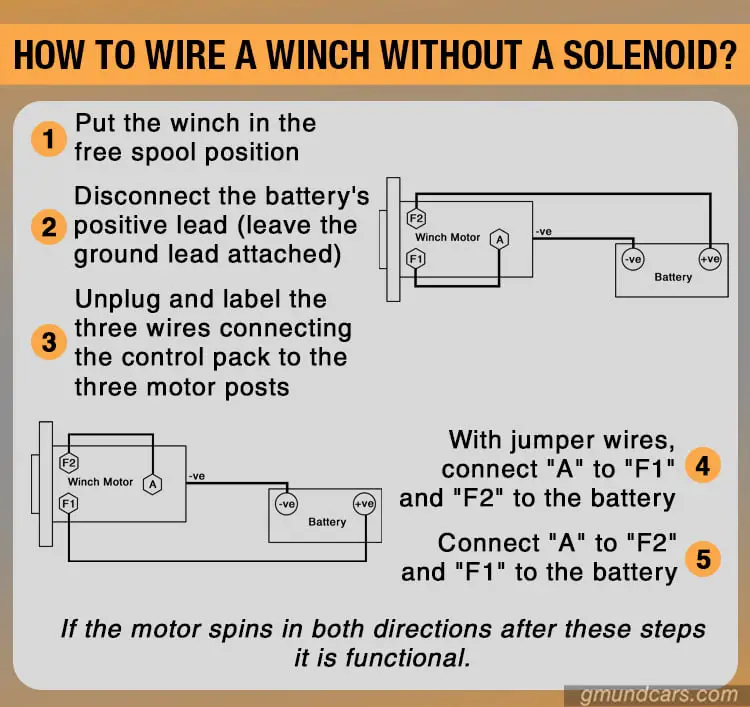

How to Wire a Winch Without a Solenoid

Step 1: Make sure the winch is in the free spool position.

Step 2: Disconnect the battery’s positive lead (leave the ground lead attached).

Step 3: Unplug the three wires that connect the control pack to the three motor posts and label them.

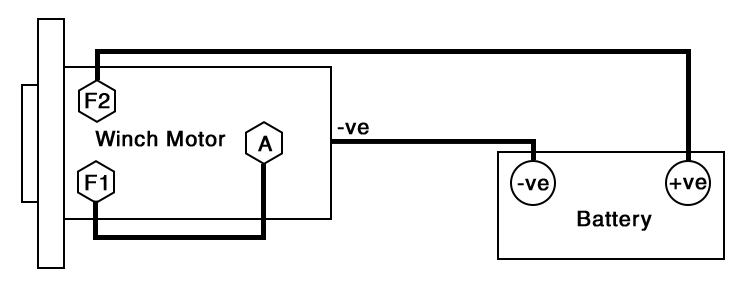

Step 4: Next to the three ports on the motor, the letters “A,” “F1,” and “F2” will be imprinted. With jumper wires (5 “-6” dead lead, 8 ga. would work), connect “A” to “F1” and “F2” to the battery. At this moment, the winch motor should only run in one direction.

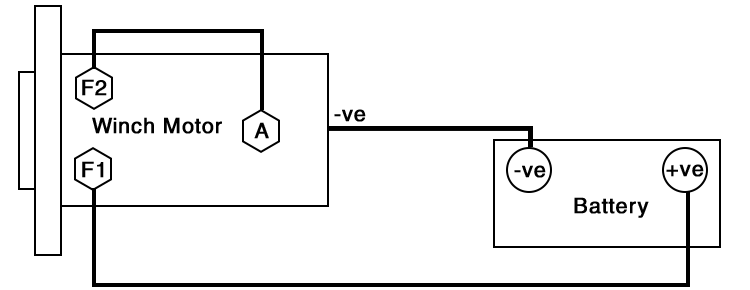

Step 5: Connect “A” to “F2” using the jumper wire, and connect “F1” to the battery. The winch motor should be going in the other direction at this stage.

If the motor spins in both directions after you follow these instructions, it is functional.

Frequently Asked Questions (FAQs)

Does a winch need a solenoid?

A solenoid is not required for every winch. Some winches have one, while others do not. Its function is to take current and stress off a switch to prevent it from burning up. Most regulators can’t tolerate a lot of currents, but solenoids can.

To safeguard the winch’s motor, you may need a solenoid. Plus, replacing a solenoid is far less expensive than replacing a winch motor if a problem arises. So, you’re not obligated to use one, but it’s a good idea.

How do you bypass a winch solenoid?

Using a power source such as your battery, connect a jumper wire to the A terminal and F1 or F2. The engine should move in both directions once the jumper wire is connected to the terminals.

You can also use a switch in place of a solenoid, but it must be capable of handling the high amperage draw of the winch.

How to wire a winch with a solenoid?

Start by connecting the winch to the solenoid through the positive and negative motor cables. Afterward, loosen the terminal nuts and secure the ring connectors over the terminal bolts to attach these wires to the designated terminals on the solenoid.

Connect the battery’s positive and negative wires to the solenoid’s battery connections, then install the battery cables from the solenoid to the vehicle’s battery and secure them to the pole terminals. Lastly, connect the two wires from the winch’s on/off switch or remote control to the solenoid’s appropriately designated terminals.

How do you wire a 12v winch?

Find the yellow and black wires from your control box and connect them to the appropriate color-coded terminals on your winch. Attach the white earthing wire and one end of a black earthing wire to the negative terminal on the winch. Then run the other end of the black earthing wire to the battery terminal negative post.

Attach the red lead to the color-coded nut on the winch. Ensure all your nuts are tight at this point. Take the final red power lead and connect it to the battery.

To make things easier, you can use a relay. The relay is programmable, so you can set it up to turn the winch off when the voltage goes below 4v and back on when that voltage rises above 5v. You can choose to give it more current on high load and less low load. Or none at all! Whatever you like.

As always, if you have any questions about this or anything else related to winches, let us know, and we’ll be sure to get back to you!