There has long been a contention regarding the best performing trailer axles and suspension. Nonetheless, it is unquestionable that every axle serves a purpose and has its own reasons for being selected over the others.

While some offer a smooth ride and seem pretty expensive, some, on the other hand, are affordable and easy to maintain.

However, out of all the axle options available, the focus has always been on the two most common axles: Torsion and Leaf Spring trailer axles.

Now, let’s get right into it!

What Is Torsion Axle And Leaf Spring Axle?

Torsion and leaf spring axles are popular trailer axles that help the vehicle’s body maintain its balance.

What Is A Torsion Axle?

Credit: dexko.com

As the name implies, a Torsion axle is a torsion arm suspension system contained within the axle tube. It is attached to the trailer frame directly with brackets that are part of the axle assembly.

The dynamism of the torsion axle is based on the traditional use and ways of handling the bar suspension. And because of this unique arrangement, the torsion axle provides better suspension characteristics than leaf spring axles.

Functions

- Trucks with torsion axle suspension have a lower bed, making loading the trailer easier.

- Torsion axle allows the trailer to ride closer to the ground because it has a lower profile.

- If half-torsion axles are used, each wheel can move on a torsion-axle trailer without the others.

What Is A Leaf Spring Axle?

Credit: dexko.com

Like the Torsion axle, the Leaf spring axle is mounted to the underside of a trailer axle, and it is made out of a stack of curved springs (leaves).

In order to lower the trailer’s ride height, the axle is draped over the springs, which offers better load stability and makes loading and unloading the trailer easier.

Functions

- Have a shock absorber to provide a cushioning effect.

- Allow a structural member to support the load on it.

- Support the trailer’s weight.

Read more: Broken Axle: Signs And Causes

Torsion Axle And Leaf Spring Comparison

The choice of which of the axles should be used depends on their similarities and differences. So, let’s get into that quickly.

Similarities

Even though they have different functions, torsion and leaf spring axles have some similarities that we cannot ignore because of their role in safely handling vehicles.

The similarities are listed below:

- Support the trailer’s weight.

- They are both serviceable.

- Provide relevant recoil for the suspension component to bounce back to normal after moving on an unequal road.

- Keep vehicles at regular standing height.

Differences

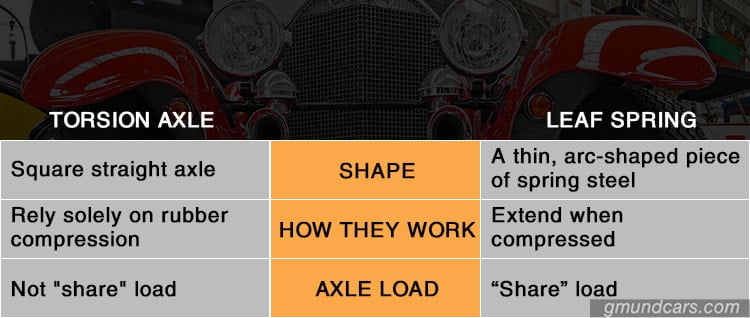

The two axles have several differences but let’s look at the three important ones.

Shape

A leaf spring axle is a thin, arc-shaped piece of spring steel with a rectangular cross-section. While the torsion axle looks like a square straight axle, the bars contain moveable parts.

How they work

A torsion axle uses cartridges inside the axle tube to control shock absorption and suspension travel. It relies solely on rubber compression to provide the necessary suspension support.

Torsion axles are connected directly to the trailer frame, which improves the trailer’s stability and construction.

On the other hand, a leaf spring axle can be coupled to the frame on both ends or probably one end, usually the front, with the other end connected by a shackle, a short swinging arm.

The leaf spring’s predisposition to extend when compressed is exploited by the shackle, resulting in softer springiness. In addition, the shackle gives the leaf spring a lot of flexibility, allowing it to take a lot of punishment without breaking.

Axle load

Torsion axles include thick cords made of rubber hidden inside the axle tubing. The rubber cords compress as each wheel rises and falls, providing a balanced wheel suspension and a regular ride. In addition, this axle does not “share” load.

When you drive over a minor bump, the wheel closest to the hump may end up carrying far more weight than the others. It’s only a temporary overload, but it might be severe – and if the trailer is fully loaded, it can even pop tires!

Each wheel moves and absorbs shocks independently of the others. Torsion axles are directly attached to the frame, which results in fewer moving parts and regular shock action. And this reduces flex by stiffening the frame.

The Leaf spring is, however, known for its rigidity and durability. The loading is done vertically at four locations on the frame.

Each side of the frame carries about a quarter of the total axle load to simplify loading to the trailer, and the stress that comes with it is easily handled.

Its suspensions, especially in multi-axle applications, are dependable for a smooth ride and tire wear.

The load from an undulating terrain is better absorbed by leaf springs. Therefore, each tire is equipped with its set of springs.

Read more: Car Warning Lights: What You Should Know

Torsion Axle Vs. Leaf Spring Axle: Which One Is Better?

Often, when you spend a little time with some vehicle owners, you get confused about which of the axles is better.

It isn’t easy to answer because the Torsion trailer axles provide a more comfortable ride and require less maintenance. But, on the contrary, the Leaf springs are more robust, less expensive, and have fewer parts to replace.

However, it would be best to stop worrying because this will help make choices.

Torsion Axle

Each trailer wheel mounts to a short trailing arm that pivots around the central axle tube, and it always has the elastomeric rods, which most people call the “rubber cords”.

The axle does not twist like a vehicle torsion bar suspension. However, there is torque and rotational resistance.

Pros

- Have an independent wheel suspension

- It is mainly welded to the trailer frame

- Make the ride smooth

- The components are not wearable

Cons

- Cannot be repaired

- It is pretty expensive to replace

- Increase the tire wear on a multi-axle configuration

Excel In Application

- Windy environments

- Rough roads

- Conditions where a lower ride height is required

- Saltwater spray environments

- High vibration applications (like wood chippers)

Leaf Spring Axle

From research, the leaf spring happened to be the most common. The name comes from the flat spring steel between the axle and the trailer. It always comes in an arc shape, and when more load is put on them, they become flattened.

Pros

- The part is always available

- Welding is not required to replace this axle

- It is cheaper to repair

- Tires are even in multi-axle configuration

Cons

- Sometimes noisy due to the metal component

- More wearable components

- It bounces more on rough roads

Excel In Application

- Dump trailers.

- Utility trailers.

- It is available in any form with just a few notable exceptions.

Read more: Nissan Dashboard Symbols and Meanings: What All Drivers Need To Know

Our Recommendations

Choosing the correct axle is as simple as calculating the loads you’ll be carrying. Whatever approach you choose, the best results will come from adequately loading your trailer to get the maximum wear out of it.

A torsion axle is recommended for trailers with light duties and soft rides. Torsion axles are not proposed for trailers with a gross weight of over 5000 pounds.

On the other hand, a leaf spring is mainly suggested when a trailer is equal in stress distribution and clean. The leaf springs give a comfortable ride when the trailer is fully loaded. Then, when the trailer isn’t completely packed, it lets a little air out of the tires for a smoother ride.

If you’re going to use a torsion axle, be sure the trailer structure is strong enough to take the extra weight, but you can tell that the leaf spring axles work for most trailers.

Conclusion

It doesn’t matter which of the axles are involved; the fact remains that there are no trailers without them.

These hidden parts are essential even though they are primarily out of sight.

Generally, trailer axles are valuable for people who rely on your trailer to make a living.

Frequently Asked Questions (FAQs)

Do torsion axles wear out?

Yes. Any axle can wear down to the point where it needs to be replaced over time. Because the suspension is incorporated into a torsion axle, replacing the axle would be the only option if the suspension portion failed.

How do I know if my leaf springs are worn?

Whenever a truck is loaded above its limit, the leaf spring automatically flattens out, lowering the truck’s height.

How do you maintain torsion axles?

Unlike the leaf spring, the Torsion axle doesn’t need day-to-day maintenance. Instead, it only requires that the trailer be towed.

How to know the weight capacity of the trailer axle?

The axle’s load capacity and weight rating are always written on the trailer’s VIN plate or sticker as the Vehicle Identification Number (VIN).

You can also use the diameter of the axle to measure the axle’s weight capacity.