Each car has a component known as an axle seal that is responsible for sealing the junction between a CV axle and the transmission or rear differential of the vehicle. The main function of an axle seal is to avert the leakage of transmission fluid or differential oil.

However, axle seal leakage can damage your vehicle, which can eventually cost you a lot with your safety as one of the things at stake.

In this article, we will take a look at the symptoms, effects, and replacement of an axle seal leak.

What Is An Axle Seal?

Credit: atpautomotive.com

The axle seal is an element or part of the vehicle that helps seal the connection of a drive shaft (CV axle) to the rear differential or transmission.

In a few all-wheel-drive automobiles, either of the CV axles at the front connects to a transfer case, and that’s why it’s occasionally called: “transfer case seal”.

Functions

- Prevent the differential oil or transmission fluid from leaking out.

- Keep lubricants away from the axle environment.

- Allow the axle to rotate freely.

- Prevent debris, dust, and water from entering the installation.

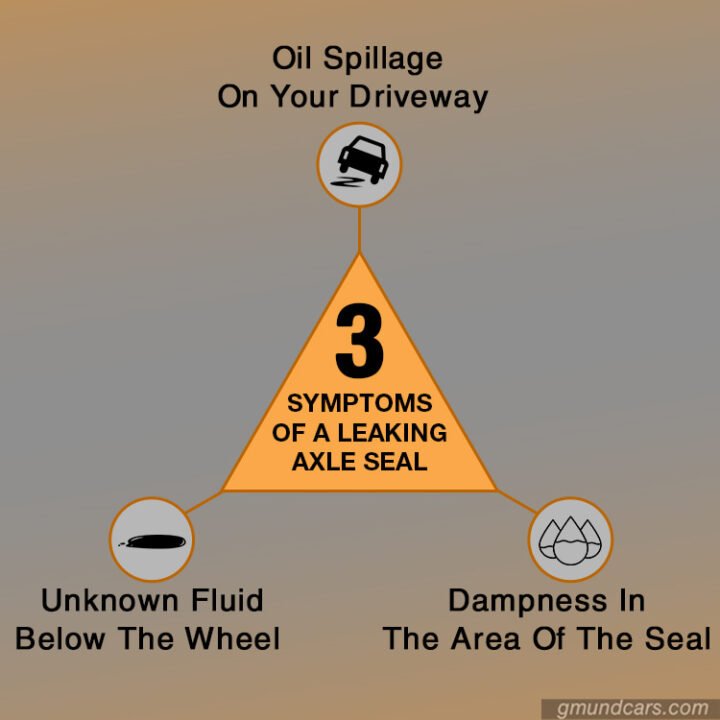

Symptoms Of A Leaking Axle Seal

An axle is an essential part of the vehicle that can create a slew of issues with your transmission system when it fails. Here are a few warning symptoms you should be on a lookout for:

Oil Spillage On Your Driveway

One of the first indicators of an axle seal leak is pools of oil under the automobile. Oil tends to spill out as the seal rips and splits, and this is usually obvious after the vehicle is stationary for a few hours on the driveway.

Dampness In The Area Of The Seal

A moist area surrounding the seal is another symptom of an axle seal leak. When leaking fluid makes its way into the exhaust system, it can cause a burning odor when the exhaust is hot.

The leak could also contaminate your brake shoes, resulting in strange noises and a reduction in braking power. As such, it’s best to check the area surrounding the seal regularly.

Unknown Fluid Below The Wheel

Another sign of an axle seal leakage is when a reddish-brown fluid starts dropping behind the front left wheel that attaches the driveshaft to the transmission.

As the fluid keeps leaking, the transmission fluid level drops, and transmission begins to slip. So while an oil stain in the driveway is a common symptom, it does not always occur because the axle seal leaks more when driving on the highway.

Read more: CV Axle Boot: Overview, Signs, And Replacement

Causes Of A Leaking Axle Seal

The primary cause of a leaking axle is an improper installation or poor maintenance of an axle seal. However, the axle seal can wear out or get damaged over time, and this can cause it to leak. So it is best to check and replace the axle seal when damaged.

Effects Of A Leaking Axle Seal

Credit: youtube.com

The effect of an axle seal that’s leaking varies depending on the level of leakage.

If large amounts of fluid leak away, the leaking part (transfer, transmission, or differential unit) may worsen. If it is a minor or little leak, and repair is impossible at the moment, you may be able to drive it for the time being as long as you are topping up the differential oil or transmission fluid.

When you fail to keep up with its regular maintenance, the bearings and gears will eventually wear out, and the axle will stop working completely, potentially while driving at high speeds. As a result, you might probably lose control of the vehicle and crash, possibly injuring or killing someone.

The axle seal should be repaired as soon as possible since the fluid can harm brake components because it is not advisable to drive with a leaky axle seal for your safety. However, to keep your gearbox working smoothly, you must make sure the fluid in it is full.

National Oil Seals 710685 Axle Shaft Seal

Read more: Front Axle Of A Car: Types, Functions, And Replacement

How To Replace The Axle Seals

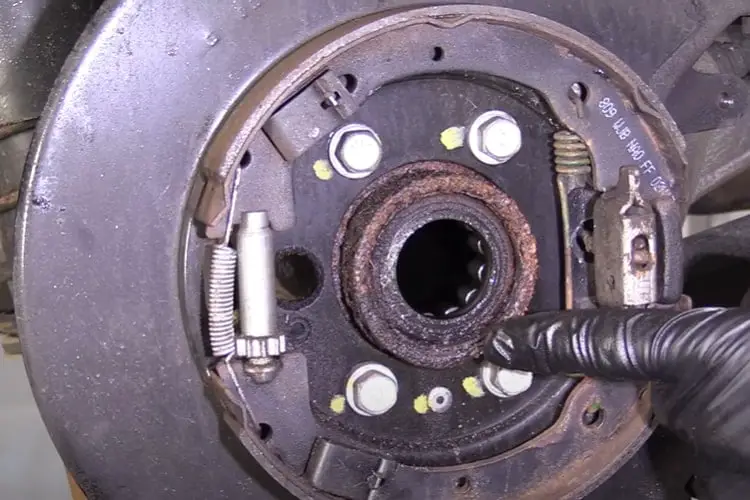

The axle seals will fail when a visible leak or a large puddle of gear oil forms beneath the car. And this might cause a lot of severe damage like brake failure, saturated brake pads, and shoes.

Also, in severe circumstances, an axle leak might cause serious damage to the differential ring and pinion as well as the bearing assemblies, perhaps destroying the entire back axle.

So before you begin to experience this, it is always recommended to replace both seals in the back axle. When replacing axle seals, you must access the differential housing in the rear axle and remove the axle shafts. You can remove both axle shafts simultaneously while removing the axle seals.

Tools needed in replacing the axle seals:

- Brake cleaner

- Hydraulic jack

- Differential fluid

- Plywood

- Hammer

- Ratchet

- Scraper

Below is a step guide on how you can replace your axle seal:

Step 1: Raise and secure the vehicle

Put your wheel chocks in front and behind either of your front tires to secure your vehicle; it will hinder the car from moving.

Next, lift your vehicle by placing your hydraulic jack at the lifting locations specified in the owner’s manual for your car. It will be easier to remove when the axle has support from the jack stands.

Lift the axle high enough to raise the wheel off the ground, and place a jack stand on both sides underneath the vehicle and plywood. Release the hydraulic jack locking mechanism on the handle to lift the car.

Set the vehicle’s gears to neutral then, remove the wheel bolts, then the vehicle’s wheel.

Step 2: Remove the brake rotor

To detach the brake rotor, remove the wheels, then remove the brake caliper from the vehicles using a ratchet.

The brake caliper is the component that holds the brake pads in place and delivers pressure to stop the vehicle. So, you must remove it first. Also, you should note that some brake calipers come with brackets, and the number of brackets a brake caliper has depends on the type of car.

Once you have removed the brake caliper, slide the brake rotor straight off the axle flange (the surface your wheel mounts to) and expose the entire flange if you don’t have a brake caliper bracket.

Loose the two mounting bolts that secure the brake caliper bracket if your car has one, after which you can remove the brake caliper rotor.

Note: The axle flange shows when you remove the brake rotor.

Step 3: Drain the differential

To drain the differential, you must first remove the bolts for mounting; it helps to empty the differential.

Then place the drain pan under the differential to drain all the liquid. Scrape between the differential cover and the axle house with your scraper to separate the differential cover from the vehicle. Remove the last bolt and place the cover and mounting bolts aside.

Step 4: Remove the axle retaining clips

To detach the axle retaining clips, you must rotate the driveline that goes into the differential and closely watch the pinion and differential ring as it rotates until you see a small retaining bolt used to hold a long pin in the center of the spider gears.

When you have done this, place the carrier in a way that will allow you to pull out the large pin without rotating the axle.

Remove the retaining and mounting bolts but save one at the top of the differential cover to empty the differential and push the large pin out of the axle. Then, go ahead to take out the differential cover from the vehicle.

Step 5: Remove the axles

Use the seal puller to hook the inner part of the seal. Then, slowly and steadily, push the pry until the seal begins to lift out. Then, pull or push, depending on your current position.

Altogether remove the seal and use the brake cleaner to clean the inside of the axle tube and wipe off the area to place the seal. Then, take the new seal and look for the correct installation tool.

Begin to install it gently. Then, with the seal in the proper location, tap it into place with a hammer until the axle housing is flush and flat.

After you’ve installed the seal, rub some differential fluid around the inside using your fingertips. Then, repeat the same process on the other side.

Step 6: Install the axles

To install the axles, you must gently put the axle end into the seal without pinching it, and once the axle is fully seated in the seal, check that the sealed package is not rolled up or broken.

Then slide the axle over the end of the axle slot and push out the axle shaft. After the axles have been mounted and secured, slip the carrier pin into the carrier assembly.

Step 7: Install the differential cover

Using a scraper, clear the surface of the old silicone from the cover and differential housing by removing all dirt. Then, use the brake cleaner to wipe the mating surfaces of the differential cover and axle housing.

Now, place the differential cover on the axle with the mounting bolts available. Hold the lid in one hand while threading the bolts with the other and apply the torque to the mounting bolts.

Step 8: Add differential fluid

Remove the fill plug from the right or left side of the differential housing, depending on its side. It may be difficult to find in some instances, so you may need to scrape off old grease or mud to see it.

After this, check the amount of differential fluid you need to fill the differential housing in the owner’s guide, then go ahead to fill it. However, while filling, you should ensure you feel the oil level with your finger to avoid overfilling that might result in leaks.

Also, the brake parts must be replaced. And to replace it, you might need to use a C-clamp to compress the caliper if it doesn’t go over the rotor when mounted. Tighten the brake caliper mounting nuts according to the manufacturer’s torque guidelines.

Put the wheels on, then apply the parking brake on the car after locking the back wheels. It will gradually help you tighten the nuts on your wheel before returning the vehicle to the ground.

Step 9: A test drive

After completing all necessary steps above, test-drive your vehicle for a short trip. This will aid in the flow of differential fluid through the axle.

The test drive should be carried out with proper attention to the vehicle in case there’s still any leakage. If none, then all is almost set.

After the test drive, remove the fill plug on the differential to verify the fluid. Then, check the level with your finger and add the desired quantity if low.

Read more: Broken Axle: Signs And Causes

Conclusion

The axle seals keep the differential fluid while keeping dirt, dust, and water out. Once polluted, it can quickly deteriorate fluid, causing bearings, seals, and even important components such as the ring and pinion to fail. Monitor your axles to save yourself from unexpected damage and extend your vehicle’s life.

FAQs

Is it safe to drive with a leaking axle seal?

It is possible to drive with an axle seal leakage for a short time if the leak is small in size.

How much does it cost to replace the axle seal?

Depending on the type and model of your car, the cost of replacing axle seals is from $150 – $600. It’s essential to seek a solution for a leak sooner rather than later if you notice one, as destroying your transmission is an expensive repair.

Should both axle seals (left and right) be replaced at the same time?

No, repairing both axles at the same time is unnecessary. If one axle seal fails, it does not necessarily signify that the other will fail soon.