The complete guide to master any grease gun

Best pistol grip grease gun

Best lever grip grease gun

Best pistol grip grease gun

Best lever grip grease gun

Air-powered grease guns use compressed air delivered by electric-powered or gas-powered compressors through hoses. These guns create a steady flow of air pressure, which forces the lubricant out of couplers into fittings. When pushing the trigger, you dispense a consistent flow of lubricant without straining yourself.

However, pneumatic grease guns would require you to have a functioning compressor on hand to use them.

Best pneumatic grease gun

Electric grease guns use powerful motor drives to deliver lubricants and are the most common alternative to air-powered counterparts. They are corded tools that you need to plug into an appropriate and uninterrupted power source to use continuously. Like the pneumatic grease gun, you apply the lubricant by pressing the trigger.

Battery-powered grease guns are operated the same as electric ones. The only difference is that they are cordless and should be charged before use. You could easily transport them as you would with manual grease guns, carrying tasks much faster.

Now you might wonder what type of grease you should use and how to load them in grease guns. Hardware stores provide all kinds of grease but do not worry, as there are already available pre-refilled cartridges that make it easier to load. In the next part of the article, you would learn how to load lubricant into a grease gun.

Best 18V cordless grease gun

Best 20V cordless grease gun

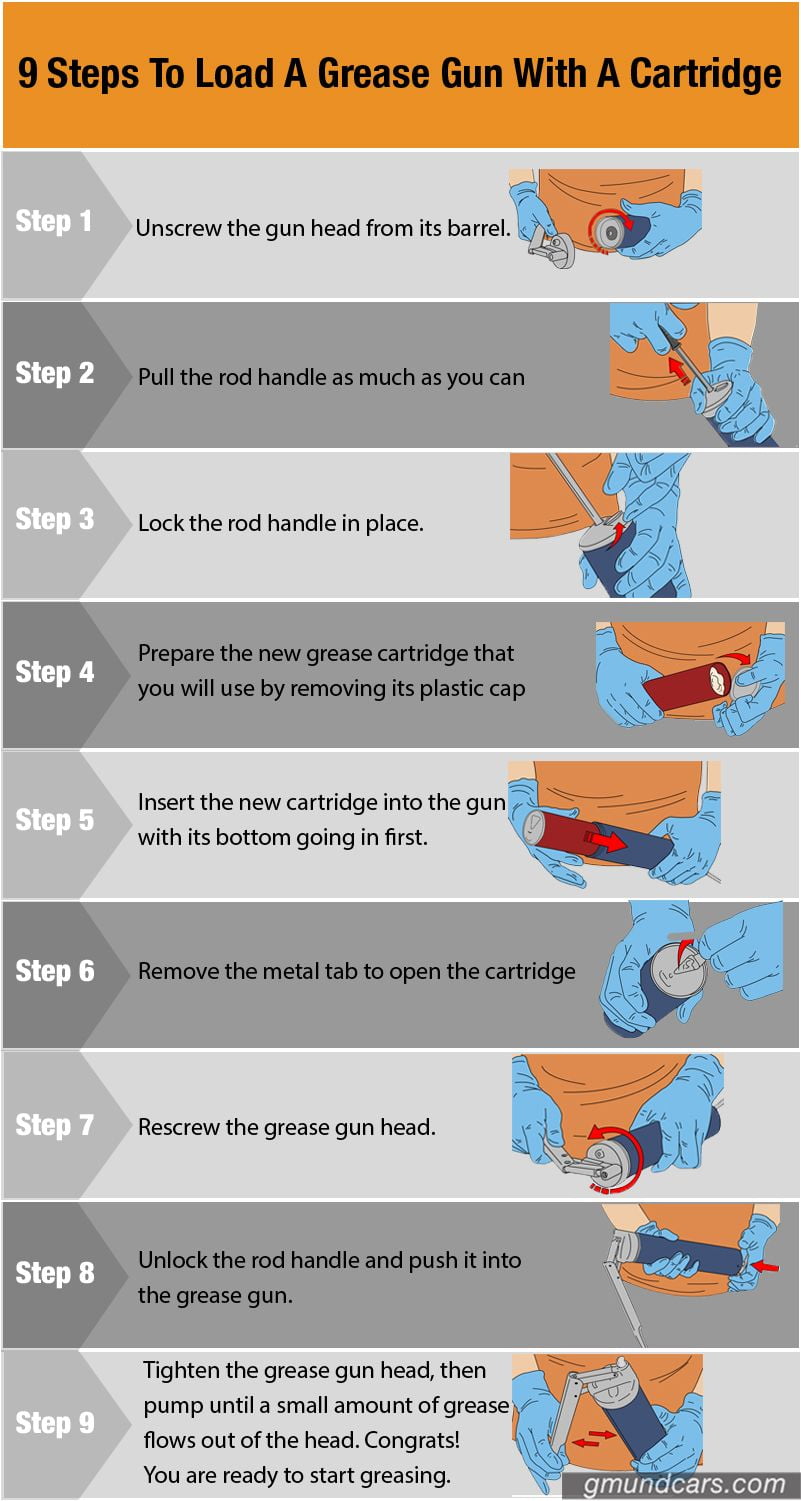

Using pre-filled cartridges to load a grease gun is the fastest and simplest way, which leaves the mess out and is easy to dispose of when it runs out.

Step 1: Unscrew the gun head from its barrel.

Step 2: Pull the rod handle as much as you can.

Step 3: Lock the rod handle in place.

Step 4: Prepare the new grease cartridge that you will use by removing its plastic cap.

Step 5: Insert the new cartridge into the gun with its bottom going in first.

Step 6: Remove the metal tab to open the cartridge.

Step 7: Reattach the grease gun head. Make sure to leave some space to allow air to escape.

Step 8: Unlock the rod handle and push it into the grease gun.

Step 9: Tighten the grease gun head, then pump until a small amount of grease flows out of the head. Congrats! You are ready to start greasing.

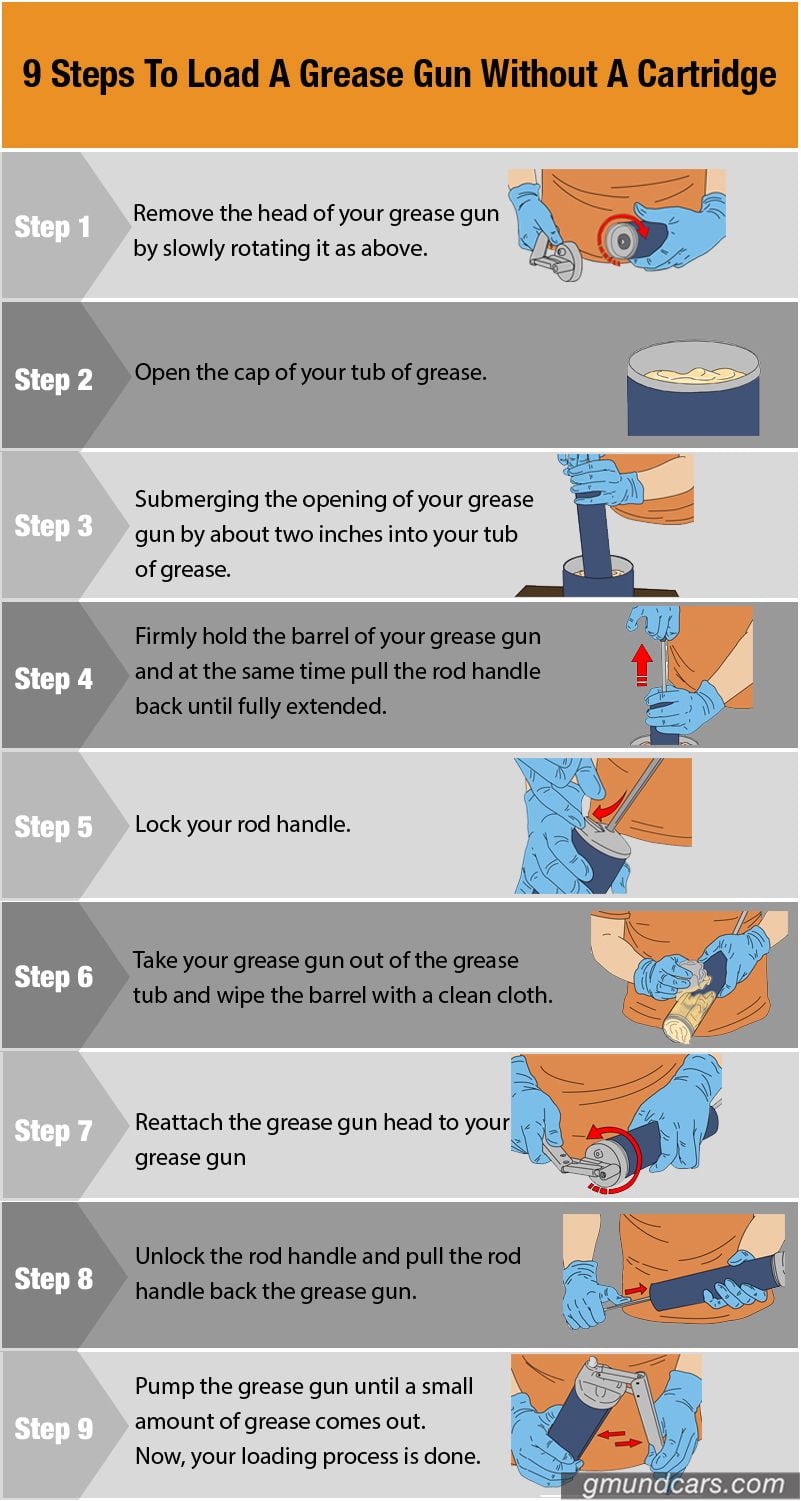

Loading a grease hun without using a cartridge can save you a few dollars. For this, you would need a tub of grease and read the guide below:

Step 1: Remove the head of your grease gun by slowly rotating it.

Step 2: Open the cap of your tub of grease.

Step 3: Submerging the opening of your grease gun by about two inches into your tub of grease.

Step 4: Firmly hold the barrel of your grease gun and at the same time pull the rod handle back until fully extended

Step 5: Lock your rod handle.

Step 6: Take your grease gun out of the grease tub and then wipe the barrel with a clean cloth.

Step 7: Reattach the grease gun head to your grease gun.

Step 8: Unlock the rod handle and push the rod handle back into the grease gun.

Step 9: Pump the grease gun until a small amount of grease comes out. Now, your loading process is done.

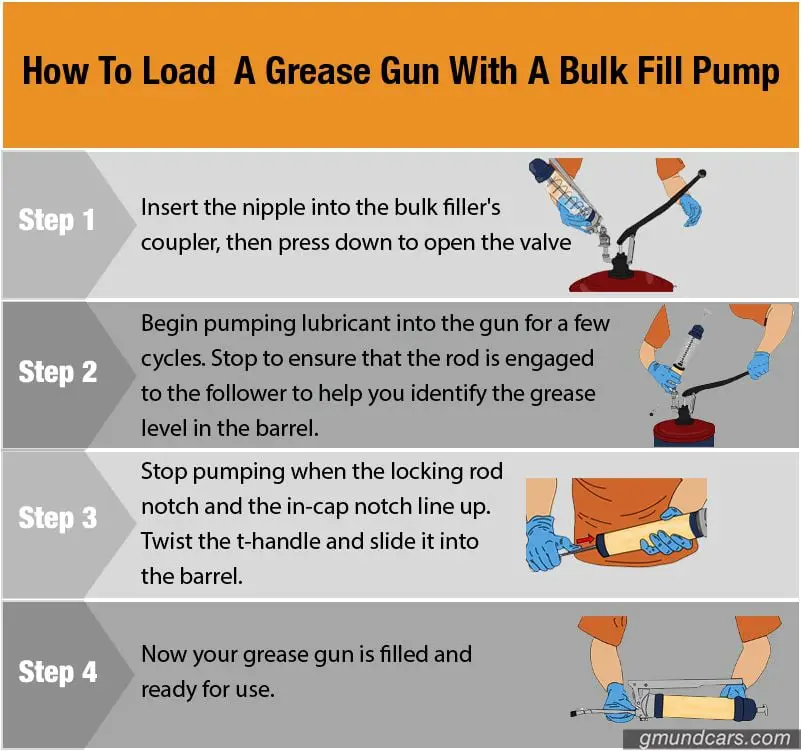

There is another way to load a grease gun without using a cartridge besides bulk filling via suction. This method uses a bulk filling with a manual pump through an attached filler nipple on the grease gun.

Step 1: Insert the nipple into the bulk filler’s coupler, then press down to open the valve.

Step 2: Begin pumping lubricant into the gun for a few cycles. After that, stop to ensure that the rod is engaged to the follower to help you identify the grease level in the barrel.

Step 3: Stop pumping when the locking rod notch and the in-cap notch line up. Twist the t-handle and slide it into the barrel.

Step 4: Now your grease gun is filled and ready for use.

If you are having trouble pumping grease out of the grease gun, most of the time, the air is trapped inside. This is where “bleeding” your grease gun comes in. Bleeding a gun means releasing the air out from an air bleed valve attached to your grease gun. It prevents airlocks and makes sure that the gun works smoothly.

Here are tips on how you can bleed a grease gun:

When you unscrew the barrel back by a little bit, it will create more airspace. Loosening the tube would help you to bleed out the air, as it would produce more pressure.

When finishing loading a grease gun, remember to press the air valve on top of the gun to bleed the air out.

Simple to bleed your grease gun, right? This bleeding will make your job easier no matter what types of grease guns you use.

After knowing how to load and bleed a grease gun appropriately, the best part of using a grease gun is its application in machinery. Follow these six quick steps on how to apply grease properly:

Select a target location to apply the grease. Targeting a specific spot instead of applying grease to all parts of a mechanism ensures efficiency when using the grease. Determine the amount of grease required per area and the type of grease necessary for the job. Checking the work order ensures that you do not waste any lubricant; you save time and complete tasks quickly.

Use a clean, lint-free cloth to clean grease fittings before greasing. A lint-free cloth does not shed fabric fibers, which could clog and cause wear on the grease gun overtime. Besides, you could use disposable lint-free paper-based products to pre-clean the fittings.

Double-check to see if the grease gun is functioning correctly, as grease needs to flow consistently and smoothly so you could apply the grease accurately.

Properly load the gun and bleed out air trapped at the top of the gun before attempting to use it. Attach a tube with a nozzle on the gun’s head for hard-to-reach areas.

Calibrate your grease gun by measuring the amount of grease produced per pump or by slowly squeezing the trigger. If you have one, use a scale to measure the output accurately which will give you an idea of how much grease you would need to apply.

Prime the grease gun by pumping it a few times until grease comes out.

Now you can apply the grease to your machines. Place the lubricant onto the designated areas as needed. For bearing cavities, connect the nozzle to the nipple and fill the void until you feel a slight resistance against the lever or trigger. The resistance means that the cavity is now full, and you can disengage the nozzle from the nipple carefully.

However, make sure not to overdo the filling procedure as it could damage the machine or even cause injury.

After the filling process, wipe off any residual grease from the nozzle and fitting using a lint-free cloth or paper-based products. Store the grease gun with the barrel bottom pointing downwards, then put the barrel cap back.

As simple as grease guns may seem to operate, they still deserve respect and should be used and cared for following guidelines. On their own, grease guns are already equipped with safety devices to avoid injuries. However, their effectiveness depends on your understanding.

As with any equipment, hardware, or tool handling with moving parts, it is always in your best interest to look out for your personal safety:

Maintaining good upkeep of your surroundings is extremely crucial when using these tools:

Before using grease guns, it is only right for you to know how to maintain them well. Here are five excellent quick tips for you to keep grease guns properly functioning with repeated use:

Q. How do you know when a grease gun is empty?

A. Just pull out the t-handle until you hit the follower plate inside the barrel, which pushes the grease. The length of the rod sticking out tells you how much grease is left. Therefore, when you pull the handle, and no rod is coming out, it means your grease gun is empty.

Q. Why does my grease gun leak?

A. Grease could leak from grease guns when constant pressure is applied to them by the follower plate. Grease is a combination of oil and a thickener, which separates when not used for a long time. When exposed to continuous pressure and hot temperatures, the oil finds its way out, usually leaking at the bottom of the gun.

Q. How do you stop a grease gun from leaking?

A. Most grease guns, depending on the quality, leak over time, and there is not much you can do about it. However, you can minimize the mess it creates by placing a catch bin under the grease gun when you store it. You could also use a barrel cap, which catches leaks and drips coming out from the gun’s bottom.

Q. How much grease comes out of a grease gun?

A. Usually, a lubricant shot dispenses varying amounts of grease subject to the grease gun’s size, condition, and model. They typically range from 0.5 grams to more than 3 grams per pump.

Q. Why does my grease gun not work?

A. The most common reason for your grease gun not working is the trapped air at the top of the gun. You could quickly fix the issue by following the proper steps on how to bleed a grease gun in this article

Machines with moving parts require lubrication to increase their working performance and extend their life. Therefore, knowing how to apply grease is an essential job, especially if you own machinery.

After reading this article, you now become fully skilled at loading, bleeding, using, and maintaining a grease gun. So what are you waiting for? Get your grease gun and start lubricating!