Need tools for your project? Toolbox, a tool rental marketplace, might be worth a look.

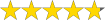

Application

There is no right tool for every situation. Depending on what your tasks are, you should pick the right one.

Impact driver

Impact driver may look like a simple drill, but you can use it for various applications since it has a lot more power. It is used to drive screws into various kinds of materials.

This power tool exerts hammering blows to get high rotational torque. With the help of impact drivers, you can drill through soft metal, wood, and even bricks!

Whether you are a professional with a lot of experience or an amateur with an interest in home improvement projects, an impact driver is a useful tool to have.

Impact wrench

Ever been to a car repair shop? Seen that high-powered tool the mechanic uses to change tires?

It is an impact wrench! You can remove or tighten bolts, fasteners, and screws with the help of impact wrenches.

Usually, impact wrenches are used on cars – such as removing lug nuts – since they deliver much more power than what you need for projects around your house.

They are also commonly used in assembly lines or construction works.

Drive

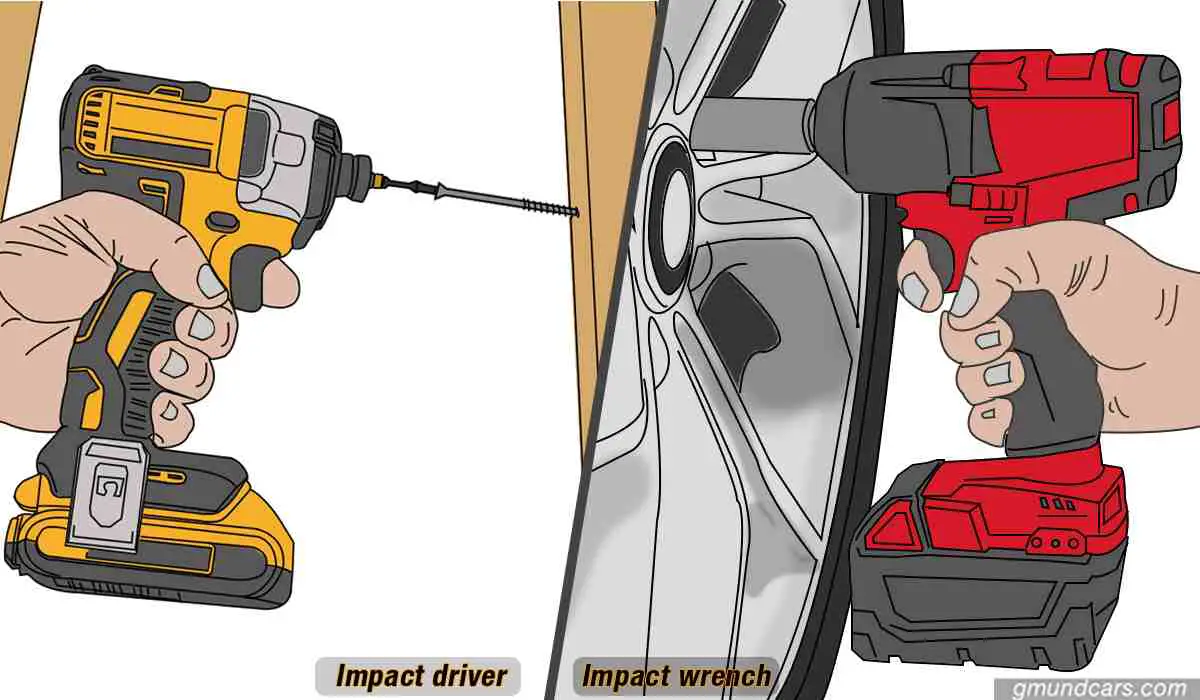

One of the major differences between an impact driver and an impact wrench is the drive style.

Impact Driver

Impact drivers usually have a 1/4″ hex collet drive that you can attach to different bits in various shapes. And this lets you turn all kinds of screws in your house.

With the help of hex-shank to square drive adapters, you can turn your impact driver into an impact wrench using hex-shank to square drive adapters.

This will allow you to attach a socket to the impact driver. And now you can turn all small fasteners or tighten some nuts on your bicycle. However, you will experience torque loss, and the bit may wobble a little.

To me, it’s actually not a big deal since there are so many light-duty tasks this adapter can pull off!

Impact wrench

Impact wrenches use square drives. Attach a socket to the square drive, and you can work with different nuts and bolts! You can use a square drive bit holder to turn it into a 1/4″ hex shank drive and use it to turn screws. But you can also use bit sockets, much easier!

As impact wrenches have a large range of performance levels, they have more specialty versions. There are three commonly used square drive sizes. These are:

- 1/2″ drive: This is the most common drive size. It is used in a variety of mechanical applications and home garages.

- 1/4″ and 3/8″: These drive sizes are used for small tasks and easily fit in tight spaces.

- 3/4″ and above: If there are any extra heavy-duty tasks that require extreme power, then these drive sizes will be perfect for that.

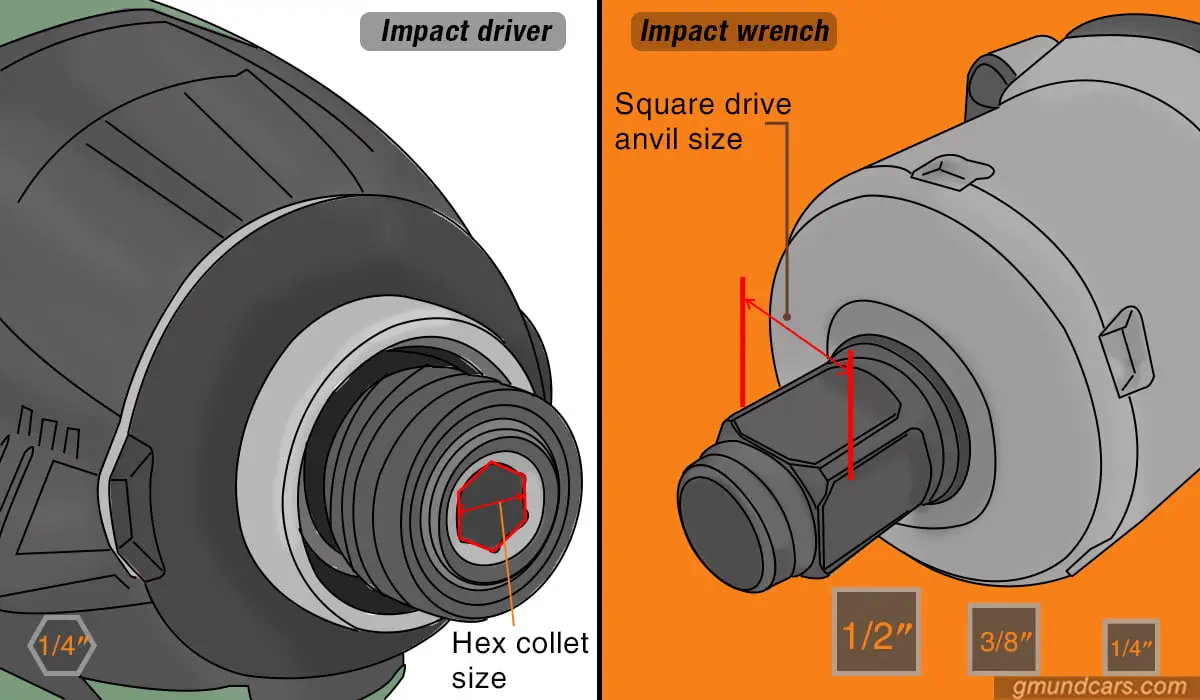

Motor

Impact Driver

Torque range: 1,200-2,000 in-lbs (100-167 ft-lbs)

The torque of impact wrenches is measured in in-lbs. Usually, impact drivers meant for DIYers have a torque range of 1,200 in-lbs to 2,000 in-lbs.

Heavy-duty impact drivers are also available – around 4200 in-lbs – but they are hardly used around the house.

Want to convert the torque measurement from in-lbs to ft-lbs? Since there are 12 inches in one foot, all you need to do is divide the figure by 12.

For example, let’s suppose you have an impact driver with a torque rating of 1,500 in-lbs. To get the rating in ft-lbs, divide it by 12. This will give you a torque rating of 125 ft-lbs.

Speed range

When it comes to speed, impact drivers are the overwhelming winners.

- RPM range: 2,800-3,400 (maximum speed, no load)

As the speed increases, so does the RPM. The higher RPM, the quicker you turn screws. Depending on the material’s hardness, you can set the right RPM for your tools.

For soft material, a low setting of RPM(around 1,300) is enough. You don’t want to over-tighten the screws or even break the material’s surface you’re working on.

For harder material, you should set the speed to 2,000+ RPM.

When choosing an impact driver, you should pick one with a variable-speed trigger. Control the speed, control the precision!

- IPM range: 3,000-4,000(maximum speed)

IPM means the impacts per minute. It tells you how many times the internal hammer strikes in 60 seconds. The higher RPM, the higher IPM.

Look for a high IPM rating since it will make your tasks easier. It’s because IPM helps to kick the fasteners in and out quickly when they face resistance. Besides, more IPM makes it easier to keep the screws or nuts stay steady in position. The lower IPM, the harder it gets to control the tool!

Similar to the RPM rating, the IPM rating varies according to the nature of the task.

Note that higher IPM does not mean higher torque.

Impact wrench

Loosening and fastening nuts and bolts require a lot of torque. That’s why impact wrenches’ motors are much more powerful than impact drivers’.

Torque Range: 150-1,400 ft-lbs

When buying an impact driver, the very first thing you need to check is the rating for two types of torque:

- Fastening torque is the maximum torque the tool can fasten a nut. Once you reach this number, the impact wrench would stop turning.

- Nut-busting torque is the maximum torque the tool can loosen a nut. For example, a nut was tightened to 700 ft-lbs will require an impact wrench with at least 700 ft-lbs nut-busting torque to loosen it. This number is always significantly higher than the fastening torque.

Tips: Don’t be fooled by nut-busting torque. Some manufacturers use this number to trick customers into thinking that their products are more powerful than others. In reality, you properly never get to this amount of torque. Why? Because they may achieve this number by:

- Heat: after being torqued to 1,000+ torque, the nut will heat up significantly, and they can remove it much easier. If the nut is back to room temperature, nah nah!

- Lubrication: YES, lubrication makes everything easier!

Speed range

On the other hand, impact wrenches have significantly lower speed.

- RPM range: 1,500-3,000(maximum speed, no load)

Impact wrenches have varying speeds that depend on your needs. A cordless impact wrench usually has around 2,000 RPM. Meanwhile, an air-powered impact wrench is an outlier since it can hit up to 8,000 RPM.

- IPM range: 2,000-3,500(maximum speed)

Compared to impact drivers’, impact wrenches’ IPM is relatively lower. This means you will spend more effort to keep the tool and the fasteners to stay firmly. It’s also one of the reasons why impact drivers are better for high-precision jobs.

Power source

Impact driver

Impact drivers come in two versions – cordless and corded.

Cordless

12V, 18V, and 20V are the most commonly used impact drivers.

A cordless impact driver runs on battery power and doesn’t have an electrical cord attached to it. This means that you will not have to be near a power outlet to operate it. They are portable, and you can easily take them anywhere you need to go.

Moreover, there is no danger of you tripping over the cord accidentally or the cord making contact with water. Therefore in terms of convenience, a cordless impact driver pulls ahead of a corded one.

Corded

But the biggest problem with these is that you need a wall to plug it in, which is impossible when you are in the middle of nowhere.

In fact, you can hardly find the cored impact driver on the market. Why? Impact drivers are meant to be portable. But adding a long ass cord to it? It’s like a paradox!

Impact wrench

Similar to impact drivers, impact wrenches also have corded and cordless versions. Moreover, for mechanics, air impact wrenches are also available.

Cordless

As I mentioned above, the most common drive size of impact wrench is the 1/2″. For cordless version, there are 2 major types of 1/2″:

High Torque

- Meant for heavy-duty tasks

- Can’t fit into tight spaces

- Heavy

Mid Torque

- Meant for low-duty tasks such as in small cars

- Fit into spaces where high torque can’t

- Less torque

Corded

Just like corded impact drivers, corded impact wrenches are becoming less common than the cordless version.

However, corded impact wrenches are much more common than corded impact drivers. Why? Because impact wrenches are meant to deliver tremendous torque.

And where can you get the stable energy to bust the nuts? Yes, plug in the wall!

Air (Pneumatic)

Pneumatic impact wrenches are powered by an air compressor.

Almost all car mechanics have an air impact wrench in their shop. These wrenches give the ability to remove lug nuts at an incredible speed. However, there are no variable speed options with pneumatic tools – it is pretty much all or nothing!

Air-powered wrenches are much more powerful than electric impact wrenches. Moreover, they are relatively cheaper, but they don’t work without air compressors, which significantly add up to the price. If you consider long term cost, an air impact wrench is not a bad choice since it lasts for years while an electric one will be in a trash can within 1 or 2 years.

Another advantage of the pneumatic impact wrench is the weight. If you are going to hold the wrench for hours, this will indeed make a difference.

Still, the downside is that you need a bulky air compressor. And yes, a wall to plug in the air compressor.

For all these reasons, they are less than ideal for use at home.

Buying guide

Now that you know which one is perfect for your need, there are a few things you have to consider when buying them.

With so many different products out there, you can’t go out and buy the first one you see. Not only will it be a waste of your money, but you also will not be able to use the tool for the purpose you bought it for. Before buying power tools, there are few things that you need to keep your eye on.

Let’s see what they are!

Who makes the best impact tools?

A high-quality brand is more likely to manufacture outstanding products and tools. Moreover, they will have excellent customer service in case you have any queries. They will also offer a good warranty in case something goes wrong with the tool you buy.

A few famous tool manufacturers are:

Dewalt

Dewalt has been around for almost a century as it was founded in 1923. They sell hundreds of products worldwide, including impact wrenches, drives, saws, and a lot more.

Dewalt offers a good warranty on their products and is known for their reliability. Moreover, this manufacturer uses new and modern technology to enhance the quality of the tools.

Milwaukee

Since its inception in 1924, Milwaukee has named itself one of the best power tools manufacturers in the market. With decades of experience, you can rest assured that their products will be high-quality, albeit slightly pricey.

Ryobi

Ryobi is a well-known Japanese electronics manufacturer. They specialize in making power tools and outdoor products at affordable rates. With more than half a century of experience under their belt, they produce high-quality power tools that are loved by mechanics worldwide.

Makita

Makita is a Japanese company and has been around since 1915. They have factories worldwide and sell various power tools – the first manufacturers to produce cordless power tools.

Their tools are known for their quality and reliability. Most of them come with 3-year long warranties.

Brushless or brushed motor?

We have all heard about brushless motors and brushed motors. The main difference between them is that brushless motors use magnets to generate power, while brushed motors use carbon brushes.

Brushed tools are relatively simple and are cheap. On the other hand, brushless tools need electromagnets, so they cost a bit more. However, the value they offer is definitely worth the cost.

Brushed motors use carbon brushes, which generate heat due to friction. Since there are no brushes in brushless motors, there will be no friction. This means the tools will produce less amount of heat and noise.

Besides, carbon brushes wear over time and need to be replaced. With brushless motors, there is no need for this.

Brushless motors are more compact and lightweight. Moreover, they deliver more power efficiently. This is because there are no contact brushes, so less resistance in brushless motors.

Battery – What to look for?

If you are buying a cordless power tool, you need to take a look at its battery.

Voltage (V)

The higher the voltage, the higher the power. However, they will be heavier and, of course, more expensive.

- 12V

When it comes to weight, the 12V tool will undoubtedly be lighter than 20/18V ones. If you are going to work overhead, with your arms extended, or have to carry the impact driver or wrench around for a long time, you should get a 12V tool.

Moreover, a 12V tool will get into places where others can’t.

- 18V/20V

18V and 20V are the most commonly used. This is because they are powerful enough to pull off 90% of the jobs and compact enough to fit into confined spaces.

- 24V

If you are going to perform high-stress, heavy-duty tasks, then choose 24V tools.

Note: These numbers indicate initial voltage without workload; nominal voltage is always lower.

Capacity (Ah)

The capacity of a battery is given in amp-hours(Ah). The higher the Ah, the higher the runtime. For example, suppose a battery has a capacity of 2.0 Ah, and it provides 2 amperes of current. In that case, it should theoretically last for one hour.

Ah also decide how powerful the tools are. Here’s why:

A 2.0 Ah battery uses a single row of 5 cells. In comparison, a 5.0 AH battery uses two rows of 5 cells that are parallelly connected. What happens is that the voltage stays the same, but the current doubles.

Besides, the smaller battery has to work harder than the bigger battery to do the same job. This decreases its productivity and longevity.

For an impact wrench(18V or 20V), a battery of 4Ah or above works perfectly.

Extra battery

Having an extra battery is very convenient. When one battery is out, you can just pull another out without waiting for the battery to be charged. However, an additional battery means additional money.

Therefore, if you are on a budget, then you should just buy a battery with more capacity that will last longer.

Power or flexibility?

This may not seem like a make-or-break factor right now, but trust us, it is. When you work with cars, an inch matters!

With an impact driver, you don’t have to worry about this much. Since they are meant for low-duty tasks that require less power, they are usually compact enough to fit into tight spaces.

But if you buy an impact wrench, you need to consider what your tasks are. The more powerful a tool is, the heavier and bulkier it is going to be.

Your tasks require a tremendous amount of torque, then go for something powerful.

If you work with nuts in a confined space, choose the compact versions.

| Types of impact wrench | Torque | Flexibility | Our top pick |

|---|---|---|---|

| 1/2'' high torque |  |  |  Milwaukee 2767-22 18V high torque 1/2" impact wrench |

| 1/2'' mid torque |  |  |  DEWALT DCF894B mid torque 1/2'' impact wrench |

| Stubby |  |  |  MILWAUKEE stubby 1/2 '' impact wrench |

| 3/8'' drive |  |  |  DEWALT DCF890B 3/8'' impact wrench |

| 1/4'' drive |  |  |  MILWAUKEE 2552-20 cordless 1/4" impact wrench |

| Cordless ratchet |  |  |  Milwaukee 2457-20 M12 cordless 3/8" ratchet |

Additional features

Variable speed

Even though power tools are meant to deliver a fair amount of force, there is no need for all of it at once. You can’t use the same force for drilling a screw into wood that you would use for drilling into construction material, right?

Generally, power tools have variable speeds and different RPM ranges. Depending on the kind of work you are doing, you can choose the speed you require!

LED for dark spot

You will likely be using your power tools in dark places. If your impact driver or wrench has LEDs that you can use in such situations, that will be a bonus!

Friction ring vs. pin detent

If you are going to use different sockets frequently, their easy removal is a make or break factor.

If an impact tool has a friction ring, you can change sockets easily. Therefore, if you are going to use more than one socket for a task, a friction ring would help.

A detent pin is a spring-loaded pin that will hold the socket on the impact driver. It is a secure socket retention method. Detent pins are very tight and keep the socket securely in place.

If you plan to use only one socket all through the task, pin detent would be a suitable option.

Final words

By now, it is clear that impact drivers and impact wrenches are different power tools, even though they look a bit similar. The million-dollar question is: Which one should you choose?

There is no simple answer to this, and it depends on the kind of work you will use the tool for. Generally, if you are a DIY mechanic working on various home-based projects, an impact driver will benefit you.

On the other hand, impact wrenches are specialized and are more suited for working with cars or heavy construction materials. However, likely, you will not use an impact wrench regularly. Therefore, buying an impact driver is a sensible choice.

Happy tinkering, folks!

FAQs

1. Can you use an impact driver to remove lug nuts?

Yes, you can use an impact driver to remove lug nuts for small cars. However, you can do something doesn’t mean you should do that! Use it for lug nuts and you will break the tool someday.

2. Will a cordless impact wrench remove lug nuts?

Yes, a cordless impact wrench can remove lug nuts. However, since lug nuts usually require a lot of torque to loosen or fasten them. Therefore, keep an eye on the impact wrench’s torque rating to see if it can remove lug nuts or not.

3. Can a 3/8″ impact wrench remove lug nuts?

With a 3/8″ impact wrench you can remove lug nuts but you will face slight difficulty. We recommend that you get a 1/2″ impact wrench for better results.

4. When should you not use an impact driver?

Impact drivers are not meant for heavy-duty usage. If you are going to work with cars, assembly lines, construction materials, etc., then you should not use impact drivers.

5. Can you use regular sockets on the impact wrench/driver?

No. You can not use a regular socket with impact tools. This is because a regular socket will break or crack when used with an impact tool since it is made from a brittle material. Use impact sockets instead! Here is why.

6. Can you set the torque on an impact wrench?

Yes! You can limit the torque on an impact wrench by using a torque stick. It looks like an extension bar, except that this stick will help you torque the nuts to the specified foot-pound. Torque sticks usually come with a kit and have different colors. Each color will denote a different foot-pound amount:

- White: 140 Ft-Lbs

- Grey: 120 Ft-Lbs

- Blue: 100 Ft-Lbs

- Yellow: 80 Ft-Lbs

- Green: 65 Ft-Lbs

- Black: 30 Ft-Lbs

However, you’d better check the torque with a torque wrench after tightening a nut.