Types and sizes of sockets

Sockets can be classified into various types based on their sizes, contact points, application, and whether you’re going to use them with hand tools or impact tools. Read on to know about the various types and the jobs they are best suited to.

Need tools for your project? Toolbox, a tool rental marketplace, might be worth a look.

Socket sizes

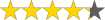

There are three factors that influence a socket’s size. They include the size of its drive, its head size, and the socket’s length. Finding it difficult to wrap your head around the first two terms? Then you must check out their definitions given as follows:

- Socket drive size: It refers to the size of the drive hole which fits at the end of the ratchet. Three of the most common socket drive sizes include:

- 1/4″ drive: It comes in handy for tasks that require low torque and high precision.

- 3/8″ drive: Since it’s extremely versatile, this drive size will let you perform almost every job at your home, car, and garage.

- 1/2″ drive: used for tasks requiring high torque or extracting car lug nuts.

- Socket’s head size: Also known as socket size, its size ranges between 5/32″ and 3-1/8″ in SAE (4mm and 80mm in Metric). These numbers will decide whether the socket will fit the bolt’s size or not.

Ratchet drive size vs. socket drive size

You may already know that common ratchet drive sizes and socket drive sizes are the same – 1/4″, 3/8″, and 1/2”.

It goes without saying that if you are planning to use a socket with a particular ratchet, drive sizes of both must be compatible. Or else the socket won’t fit. In that case, a square drive socket adapter is your savior.

SAE and metric socket sizes chart

Short form of Society of Automotive Engineers, the SAE standard comes from the Imperial, or English, system. It is based on inches and fraction of inches and was the mainly used standard on US-made automobiles throughout the 1970s.

On the contrary, the metric system has always been the preferred fastener measurement system in the rest of the world. It is more convenient than the SAE standard because the metric system predicates its measurements in millimeters (mm). All imported cars in the US have metric bolts.

SAE socket sizes chart

| 1/4'' Drive | 3/8'' Drive | 1/2'' Drive | 3/4'' Drive | 1'' Drive |

|---|---|---|---|---|

| 5/32" | 1/4" | 3/8" | 7/8" | 1-5/8" |

| 3/16" | 5/16" | 7/16" | 15/16" | 1-11/16" |

| 7/32" | 3/8" | 1/2" | 1" | 1-3/4" |

| 1/4" | 7/16" | 9/16" | 1-1/16" | 1-13/16" |

| 9/32" | 1/2" | 19/32" | 1-1/8" | 1-7/8" |

| 5/16" | 9/16" | 5/8" | 1-3/16" | 2" |

| 11/32" | 5/8" | 21/32" | 1-1/4" | 2-1/8" |

| 3/8" | 11/16" | 11/16" | 1-5/16" | 2-3/16" |

| 7/16" | 3/4" | 3/4" | 1-3/8" | 2-1/4" |

| 1/2" | 13/16" | 25/32" | 1-7/16" | 2-3/8" |

| 9/16" | 7/8" | 13/16" | 1-1/2" | 2-1/2" |

| 15/16" | 7/8" | 1-5/8" | 2-5/8" | |

| 1" | 15/16" | 1-11/16" | 2-3/4" | |

| 1" | 1-3/4" | 2-15/16" | ||

| 1-1/16" | 1-13/16" | 3" | ||

| 1-1/8" | 1-7/8" | 3-1/8" | ||

| 1-3/16" | 2" | |||

| 1-1/4" | 2-1/8" | |||

| 1-1/2" | 2-3/16" | |||

| 2-1/4" |

Metric socket sizes chart

| 1/4'' Drive | 3/8'' Drive | 1/2'' Drive | 3/4'' Drive | 1'' Drive |

|---|---|---|---|---|

| 4mm | 5.5mm | 8mm | 19mm | 36mm |

| 4.5mm | 6mm | 9mm | 20mm | 38mm |

| 5mm | 7mm | 10mm | 21mm | 41mm |

| 5.5mm | 8mm | 11mm | 22mm | 46mm |

| 6mm | 9mm | 12mm | 23mm | 50mm |

| 7mm | 10mm | 13mm | 24mm | 54mm |

| 8mm | 11mm | 14mm | 25mm | 55mm |

| 9mm | 12mm | 15mm | 26mm | 58mm |

| 10mm | 13mm | 16mm | 27mm | 60mm |

| 11mm | 14mm | 17mm | 28mm | 63mm |

| 12mm | 15mm | 18mm | 29mm | 65mm |

| 13mm | 16mm | 19mm | 30mm | 67mm |

| 14mm | 17mm | 20mm | 31mm | 70mm |

| 15mm | 18mm | 21mm | 32mm | 71mm |

| 19mm | 22mm | 33mm | 75mm | |

| 20mm | 23mm | 34mm | 77mm | |

| 21mm | 24mm | 35mm | 80mm | |

| 22mm | 25mm | 36mm | ||

| 26mm | 38mm | |||

| 27mm | 40mm | |||

| 28mm | 41mm | |||

| 30mm | 42mm | |||

SAE to metric conversion chart

| SAE | Converted to millimeter | Metric | Note |

|---|---|---|---|

| 5/32'' | 3.97mm | 5/32'' and 4mm are close | |

| 4mm | |||

| 4.5mm | |||

| 3/16'' | 4.76mm | ||

| 5mm | |||

| 5.5mm | 7/32'' and 5.5mm are close | ||

| 7/32'' | 5.56mm | ||

| 6mm | |||

| 1/4'' | 6.35mm | ||

| 6.5mm | |||

| 7mm | |||

| 9/32'' | 7.14mm | ||

| 5/16" | 7.90mm | 5/16'' and 8mm are close | |

| 8mm | |||

| 11/32" | 8.73mm | ||

| 9mm | |||

| 3/8" | 9.53mm | ||

| 10mm | |||

| 13/32" | 10.32mm | ||

| 11mm | 7/16'' and 11mm are close | ||

| 7/16" | 11.11mm | ||

| 15/32" | 11.90mm | 15/32'' and 12mm are close | |

| 12mm | |||

| 1/2'' | 12.70mm | ||

| 13mm | |||

| 17/32" | 13.49mm | ||

| 14mm | |||

| 9/16" | 14.29mm | ||

| 15mm | 19/32'' and 15mm are close | ||

| 19/32" | 15.08mm | ||

| 5/8" | 15.88mm | 5/8'' and 16mm are close | |

| 16mm | |||

| 21/32" | 16.67mm | ||

| 17mm | |||

| 11/16" | 17.46mm | ||

| 18mm | |||

| 23/32" | 18.26mm | ||

| 19mm | 3/4'' and 19mm are close | ||

| 3/4" | 19.05mm | ||

| 25/32" | 19.84mm | 25/32'' and 20mm are quite close | |

| 20mm | |||

| 13/16" | 20.64mm | ||

| 21mm | |||

| 27/32" | 21.43mm | ||

| 22mm | |||

| 7/8" | 22.23mm | ||

| 23mm | 29/32'' and 23mm are close | ||

| 29/32" | 23.02mm | ||

| 15/16" | 23.81mm | ||

| 24mm | |||

| 25mm | |||

| 1" | 25.4mm | ||

| 26mm | |||

| 1-1/16" | 26.99mm | 1-1/16'' and 27mm are close | |

| 27mm | |||

| 28mm | |||

| 29mm | |||

| 30mm | |||

| 1-3/16" | 30.16mm | ||

| 31mm | 31+mm socket sizes are available in uncommon 3/4'' drive size | ||

| 1-1/4" | 31.75mm | ||

| 32, 33, 34, 35, 36, 37, 38 mm | |||

| 1-1/2" | 38.1mm |

Download socket sizes chart pdf

What are the most needed socket sizes in your garage?

Based on my experiences, 3/8’’-3/4″ (SAE) and 10mm-19mm (metric) are generally the most commonly used socket sizes in your garage. The most common of all is 3/8” and 10mm.

How to make socket sizes readable?

One of the best ways to make socket sizes readable is marking them with paint. All you need are two paintbrushes and two paints (red and blue). You can use red paint to mark SAE sizes and blue paint to mark Metric sizes.

Socket lengths

Following are the various lengths of sockets:

| Pros | Cons | |

|---|---|---|

| Shallow length sockets | - Fit into tighter spaces | - Won’t go deep |

| Deep length sockets | - Can go for hard-to-reach fasteners | - Too bulky for tight spaces |

| Semi-deep sockets | - More in-depth access than shallow sockets - Easy to maneuver | - Not the best for general use |

Shallow length sockets

The preferred choice of DIY enthusiasts, shallow length sockets provide a lot of benefits. They easily fit into tight spaces because you can have more overhead clearance. You can therefore count on them to help you carry out repair or maintenance jobs on automobile engines.

Deep length sockets

They are widely recommended for reasons. You can use deep well sockets for both hard-to-reach and regular fasteners (as long as space is not so confined).

As DIYers, deep sockets maybe everything you need in the garage. Of course, situations when only shallow or semi-deep can solve problems will arise. But honestly, how many times? Properly close to zero!

As a mechanic, on the other hand, you must have various socket types for multiple situations.

Semi-deep sockets

Semi deep sockets provide the best of both worlds. You can count on them to deliver more in-depth reach than their shallow counterparts. At the same time, they are easier to maneuver than deep sockets in confined and restricted spaces.

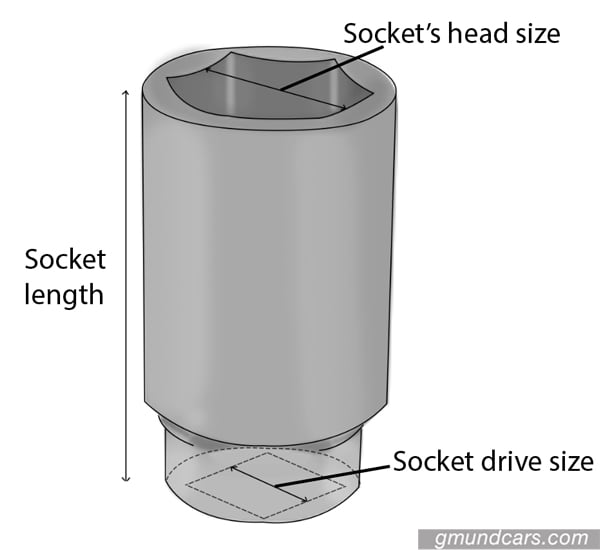

Socket contact points

The socket’s points that come into contact with nuts or heads of fasteners are known as contact points. The most popular ones are, undoubtedly, 6-point and 12-point sockets.

6-point socket

Ever wondered why impact sockets mostly come in six-point configuration?

Because these sockets let you apply huge force. That, in turn, is made possible by two facts:

- These sockets cover more area on 6-point fasteners. Thereby making themselves less likely to slip and round off the fastener.

- They have thicker walls that can withstand greater force.

That’s also why 6-point sockets can be used for higher torque tasks and jobs that require high torque.

12-point socket

Want to get your hands on a socket that will connect easily with the fastener? Then get yourself a 12-points socket. This makes them a must-have for jobs where the bolt’s precise location is hard to pinpoint and see.

Also, since they have more angles than their 6-point counterparts, 12-point sockets have a better motion range. They also work a treat in tight spaces. But if you already have a ratcheting socket wrench, this benefit becomes meaningless.

There are many situations where you’d need a 12-point socket. Examples include vehicles that use 12-point fasteners to connect their drive-shaft with the differential.

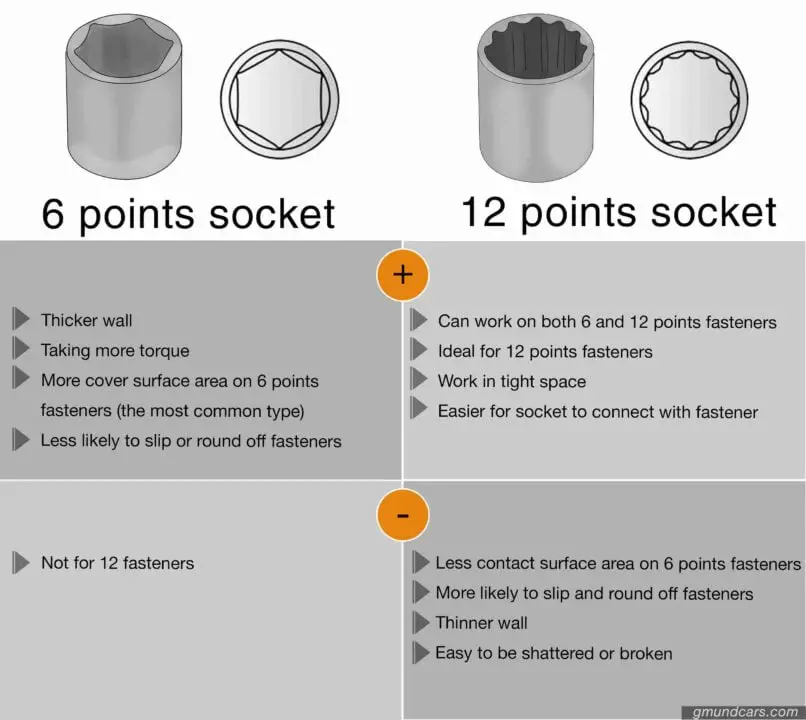

Other Types

Here are other types of sockets contact points:

- 4-point (square socket): Used on square fasteners, 4-point sockets provide a lot of grip with any kind of wrench and are inexpensive to manufacture. However, since they have only 4 sides (at a 90-degree distance from each other), your wrench can exist in only four positions, making these sockets a little inconvenient in various situations.

- 8-point (double square socket): Also known as double-square sockets, an upgrade version of the square socket and are made in a large variety of sizes.

They have extremely thick walls, partly due to their sharper edges that place more significant stress on their corners than other sockets. Their better motion range also allows them to fit square sockets with ease. You may notice technicians using the 8-point sockets in the railroad industry.

- 5-point (Penta) socket: Fitting nuts found on gas, water valves, and utility work, 5-point sockets are available in various sizes too. Some of the common 5-point socket sizes you can find on the market include 1/2” and 3/8”, among others.

- Spline socket: Designed to offer a higher strength in a more compact profile, they have a bigger contact area that allows more extensive torque application without damaging the nut and its corners. You may want to note, though, that this benefit is limited to spline fasteners.

They can be used on Torx drives, square drives, 6-point drives (SAE and metric), 12 point drives (SAE and metric). Their best application involves loosening rounded bolts.

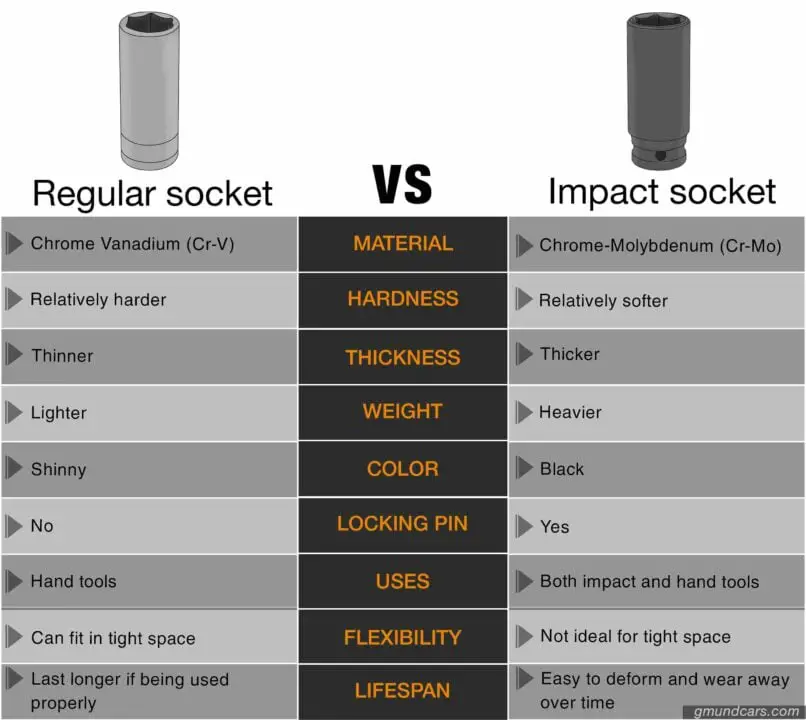

Regular socket vs impact socket

Is your socket designed to be used with hand tools or impact tools? Here’s how you can answer this question.

Impact sockets

Impact sockets – which are intended to be used with impact tools (impact wrenches, impact driver, etc.).

They also have thick walls and are mostly made of molybdenum chromium steel, which is relatively softer than chrome socket-allowing them to absorb vibration better without cracking into pieces. Most of them sport a matt and black finish due to a black oxide coating.

Such sockets come with locking pins, which keep them from falling off due to the impact tool’s vibration.

On the flip side, their thick walls restrict their utility in tight spaces. However, the difference is not that significant since manufacturers are making them thinner and thinner nowadays.

And the fact that their material is softer makes these sockets prone to deformation and wear-and-tear over time.

Despite all of their disadvantages, impact sockets are widely recommended since they are cheaper and cover almost all of your tasks.

Regular sockets

That isn’t the case with regular/chrome sockets. They boast a chromed and glassy finish, are mostly made of chrome vanadium steel, and have relatively thin walls.

As for their shortcomings, these models can only be used with hand tools – whereas you can use impact sockets with both hand and impact tools.

But they make up for this flaw with hardness and relatively long lifespan – only if you use them in the right way. Their thin wall also enables these sockets to work seamlessly in tight spaces.

Sockets for specific application

Here are different sockets alongside their applications:

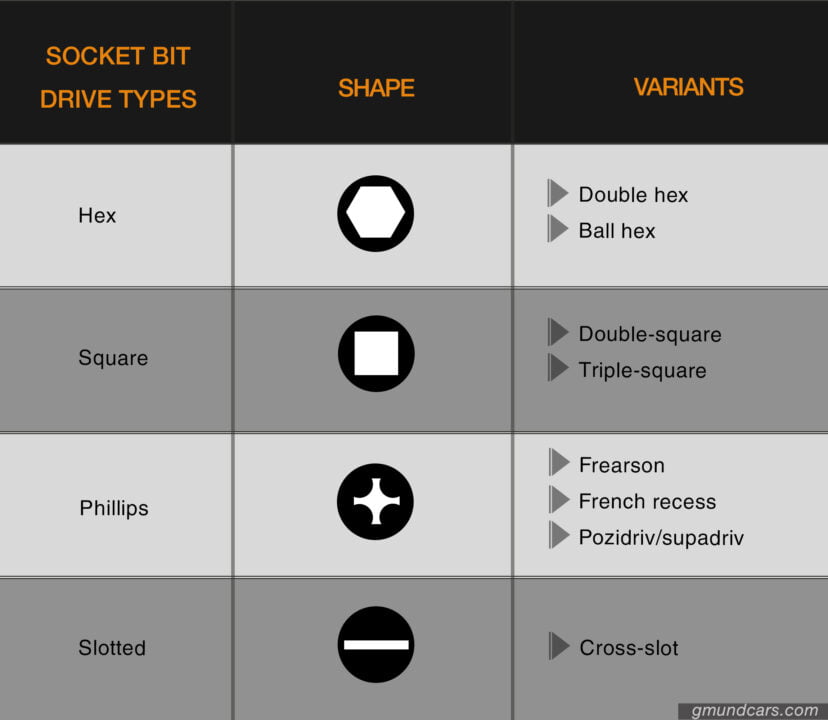

Bit sockets

As you may already know, socket bits are a combination of bits (such as a screwdriver bit) and a socket. They connect to turning tools (like a ratchet) in much the same manner as your average hex socket – by relying on a square drive socket, and are used for opening and fastening screws.

Following are the most common types of bit sockets:

Torx bit sockets and E-Torx sockets

Both of them can be identified by their 6-point star-shaped pattern. The difference between both is quite obvious – ones have bit and ones don’t. People also call them male and female Torx sockets. Make sense, right?

Torx bit sockets

Torx bit (or External Torx/Male Torx) sockets are designed to fit and turn fasteners with an internal Torx head.

The sizes of Torx bit sockets are described using the letter T followed by a number, ranging between T1(smallest) and T100(largest).

Torx bit socket sizes chart

| Sizes | Point to Point (Inch) | Point to Point (mm) | Maximum torque range (lb·ft) |

|---|---|---|---|

| T1 | .031 | .81 | 0.015–0.022 |

| T2 | .036 | .93 | 0.052–0.066 |

| T3 | .046 | 1.10 | 0.10–0.13 |

| T4 | .050 | 1.28 | 0.16–0.21 |

| T5 | .055 | 1.42 | 0.32–0.38 |

| T6 | .066 | 1.70 | 0.55–0.66 |

| T7 | .078 | 1.99 | 1.0–1.3 |

| T8 | .090 | 2.31 | 1.6–1.9 |

| T9 | .098 | 2.50 | 2.1–2.5 |

| T10 | .107 | 2.74 | 2.7–3.3 |

| T15 | .128 | 3.27 | 4.7–5.7 |

| T20 | .151 | 3.86 | 7.7–9.4 |

| T25 | .173 | 4.43 | 11.7–14.0 |

| T27 | .195 | 4.99 | 16.6–19.8 |

| T30 | .216 | 5.52 | 22.9–27.6 |

| T40 | .260 | 6.65 | 39.9–48.0 |

| T45 | .306 | 7.82 | 63.4–76.1 |

| T50 | .346 | 8.83 | 97–117 |

| T55 | .440 | 11.22 | 161–189 |

| T60 | .519 | 13.25 | 280–328 |

| T70 | .610 | 15.51 | 460–520 |

| T80 | .690 | 17.54 | 696–773 |

| T90 | .784 | 19.92 | 984–1,094 |

| T100 | .871 | 22.13 | 1,359–1,511 |

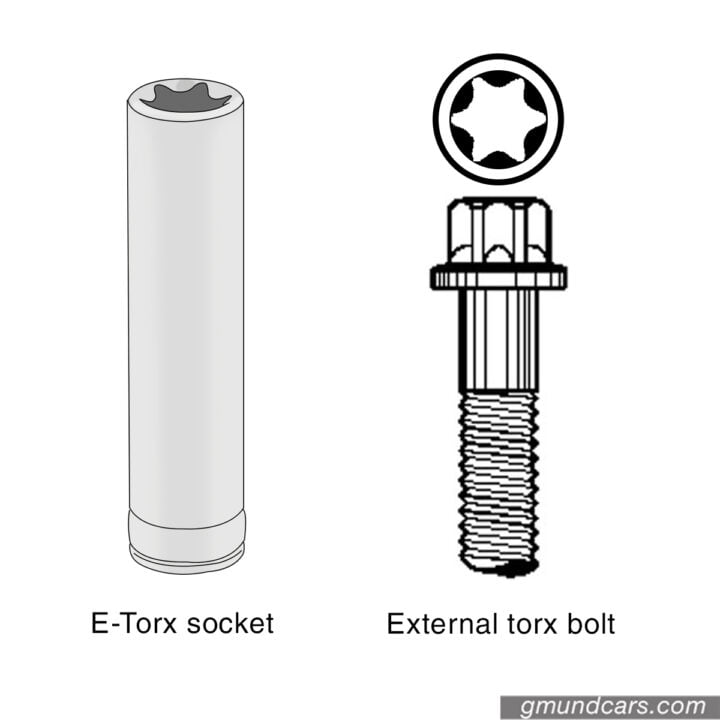

E-Torx socket

Also known as external torx socket/ female torx socket. They are not actually bit socket because, well, they do not have any bit. They are designed to fit and turn fasteners with an external Torx head.

The head size of E-torx sockets are designated by the letter E followed by a number, ranging between E4 (smallest) and E44 (largest)

E-torx socket sizes chart

| Size | Point to Point distance (inch) | Point to Point distance (mm) | Standard fastener selection (SAE) | Standard fastener selection (Metric) |

|---|---|---|---|---|

| E4 | 0.15 | 3.8 | #6 | M3 |

| E5 | 0.19 | 4.7 | #8 | M4 |

| E6 | 0.22 | 5.6 | #10 | M5 |

| E7 | 0.24 | 6.1 | ||

| E8 | 0.29 | 7.4 | 1/4" | M6 & M7 |

| E10 | 0.37 | 9.3 | 5/16" | M8 |

| E12 | 0.44 | 11.1 | 3/8" | M10 & M11 |

| E14 | 0.50 | 12.8 | 7/16" | M12 |

| E16 | 0.58 | 14.7 | 1/2" | |

| E18 | 0.65 | 16.6 | 9/16" | M14 |

| E20 | 0.72 | 18.4 | 5/8" | M16 |

| E24 | 0.87 | 22.1 | 3/4" | M18 & M20 |

| E28 | 7/8" | M22 | ||

| E32 | 1" | M24 & M27 | ||

| E36 | 1-1/8" | M30 | ||

| E40 | 1-1/4" | M33 | ||

| E44 | 1-3/8" | M36 |

Download Torx and E-Torx socket size pdf

Torx plus

Torx plus is an upgrade version of Torx drive system, they allow:

– Better torque transmission

– Better tools engagement

– Extend tool’s lifespan

A standard Torx bit will fit into a Torx Plus fasteners, but a Torx Plus will not work in a standard.

The Torx plus sizes are described by a number followed by the letter:

- IP(internal plus), ranging from 1IP(smallest) to 100IP(biggest)

- EP(external plus), ranging from 1EP to 42EP(biggest). Besides, they also have a few extra small sizes- H7EP, H4EP, H3EP, H2EP (smallest to bigger sizes, H2EP is closest to 1EP)

People also use the opposite order (such as IP14, EP14) to call them.

Are they tamper-resistant?

You can answer this question by looking at the design of your Torx bit socket. Those that are tamper-resistant have a post in the center of their head. This post prevents any straight screwdriver (or a standard Torx driver) from being inserted into the Torx bit.

Other common bit sockets

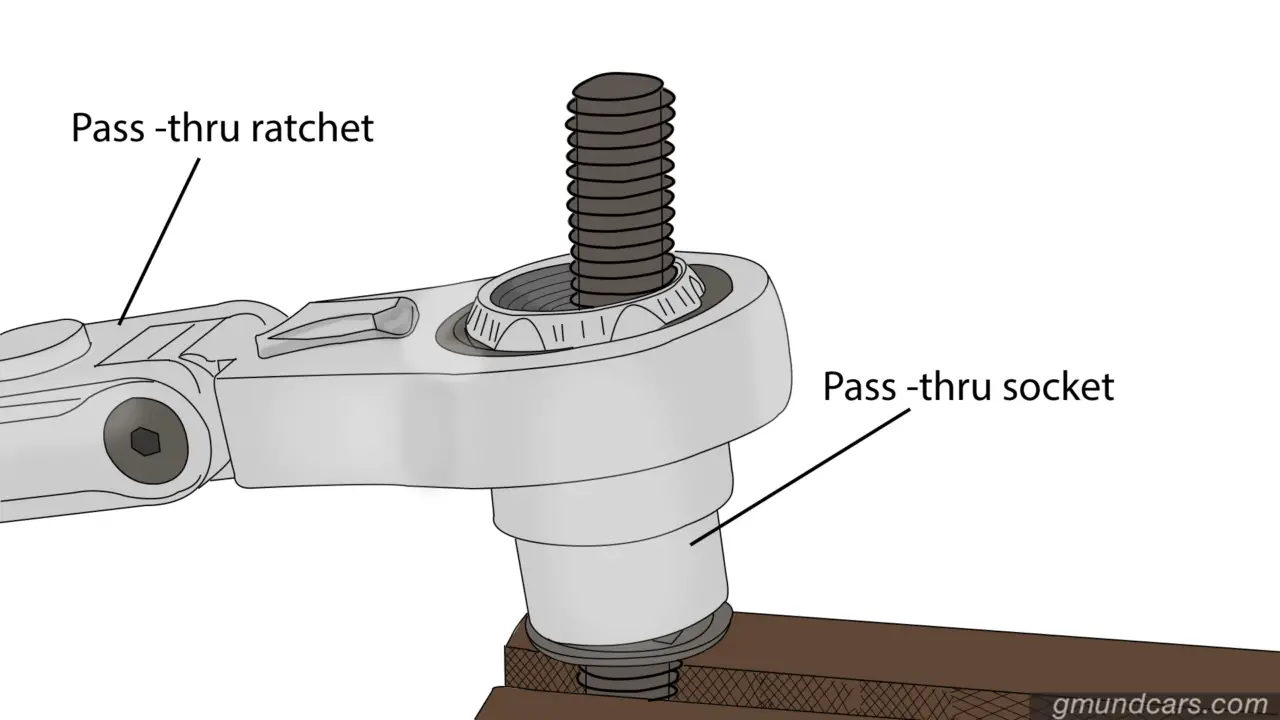

Pass-thru sockets

Designed to be used with pass-thru ratchets, these sockets allow you to work in tight spaces because their ratchet’s thickness is negligible. They have a pass-through hole in them, making them a hollow tube and allowing them to be used on any bolt, without their length posing an issue.

There’s one thing you may want to note about pass-thru sockets. They don’t work by connecting to the ratchet head’s square nub. Instead, these sockets only work with pass-thru ratchets that can clamp around their head. And if you want to use a regular socket for the pass-thru socket, you must have a pass-thru adapter.

Spark plug sockets

Their name makes it clear what ‘spark plug’ sockets are all about. They are designed to be used for fitting a spark plug into an engine. These sockets tend to be longer than your average socket and mostly come with:

- Magnetic insert

- Rubber insert

The idea is to keep the spark plug safe from dropping and damage. As a mechanic, I prefer the one with magnetic since the rubber sometimes pops out for no reason.

The fact that they tend to be long doesn’t mean that you can think of spark plug sockets as some variant of deep sockets. Both are different. While you can use deep sockets for many tasks, spark plug sockets are explicitly designed to work with spark plugs.

This difference may not sound remarkable, but it does make a lot of difference. Here’s why we’re so sure.

The specialized bed of spark plug sockets helps keep slippage at bay during work. This, in turn, makes the installation and removal of a spark plug faster with a spark plug socket. It also means that vis-à-vis deep sockets, spark plug sockets pose a reduced risk of damaging the spark plug ceramic insulator.

Spark plug socket sizes chart

The most common size of spark plug sockets is 5/8” and 13/16”. However, a variety of cars come with different spark plug sizes, which is too long to include in this article. Here is my recommendation – try to google with the keyword: “your vehicle model name” + spark plug socket sizes.

The table below shows you spark plug socket sizes you will ever encounter and their general application.

| Spark plug sizes | Application | Notes |

|---|---|---|

| 14mm | BMW (some) Nissan engines (some) MINI vehicles (such as R55, R56, R57, and R60) Motorcycles(some) Newer Asian cars. | Usually come with thin wall 12 points design |

| 9/16'' | Ford | You can use 14mm, fits more snugly since it is slightly smaller than 9/16''. 14mm plugs require 12 points socket |

| 5/8'' | V16 engines (most) V8 engines (some) | The most commonly used size. You can use 16mm instead of 5/8'', but it is slightly bigger. |

| 11/16'' | Older BMW M series | |

| 18mm | Motorcycles (most) | |

| 3/4" | Older GM cars Small engines Lawnmowers | |

| 13/16" | V8 engines (most) | Also very common |

| 7/8" | Older vehicles Tractors Aviation | Become rare nowadays |

Notes: There are a few things you MUST keep on mind when buying a spark plug socket:

- 3/8” drive: when it comes to spark plug socket, 3/8” drive size is the most useful and common

- Thin wall: Do NOT go for some “standard thin wall” socket on the market. The socket wall must be extremely thin to fit into the engine’s tight space.

- 6 points and 12 points socket: Having both types is crucial since different spark plugs require different contact points.

- Flexibility: Reaching to the spark plug is tough. That’s why you may need a swivel socket and an extension bar.

Lug nut socket

Lug nut sockets are used for…lug nuts, obviously. They are designed with

– Impact material: Withstand high torque: that’s also why they mostly and come with 1/2” drive

– Thin wall: to fit in tight spots and prevent the sockets from scratching and damaging to the rims

Beside regular lug nut sockets I mentioned above, there are a few common variations of them:

- Non-marring socket:

Such sockets come with a non-marring core and sleeve. This prevents damage to wheels, custom rims, and lug nuts. You can also remove the outer sleeve for tight space uses.

- 6 point and 7 point spline socket:

Variations of spline sockets. You can use them for 6-spline or 7-spline wheel lock lug nuts by attaching those sockets to a regular hex socket.

Multi size sockets

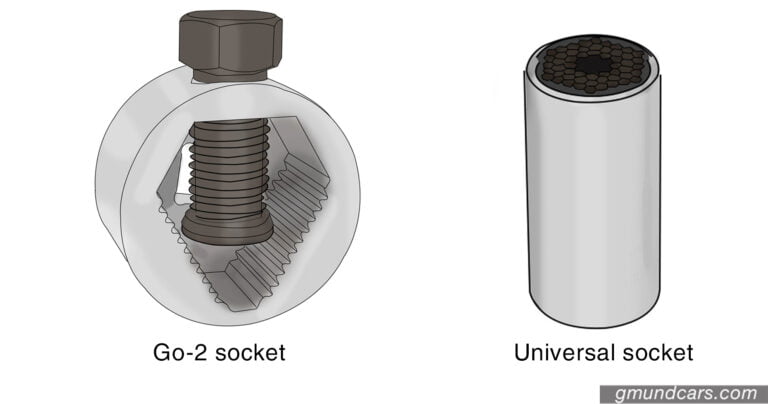

Universal sockets

Although they look similar to your standard deep socket, the universal sockets’ head is inundated with several tiny metal pins. These pins are spring-loaded. Once you place the socket over the fastener’s head, the pins that are face-to-face with the fastener head will be depressed.

This will allow the pins on the sides to surround the fastener head and grip it. This mechanism makes universal sockets an ideal choice for DIYers who use sockets on a daily basis. But that doesn’t mean that everything is hunky-dory about universal sockets.

Shortcomings of universal sockets

Since universal sockets have several moving parts (pins), they wear faster than your standard sockets, which don’t have as many moving parts. And even before they’ll eventually wear out, the pins will be regularly inundated with grease or oil, thereby rendering the socket useless until you clean the pins.

As if that shortcoming wasn’t damning enough, universal sockets suffer from another flaw. The surface area of the pins that will come into contact with the fastener is less. That’s why you cannot apply the same amount of torque with a universal socket that you can with a standard or deep socket.

However, suppose you try to apply more torque. In that case, the fastener may get stripped (at best) or damaged (at worse), thereby becoming useless for any future task. All these shortcomings are the reason why most professionals advise against using universal sockets.

Go2 sockets

The Go2 socket is an adjustable socket and a bolt-and-nut extractor. It fits sizes ranging between 10mm (3/8″) and 20mm (3/4″) and grips around nuts and bolts – or basically anything that could fit in its threaded cavity. You can increase/decrease the size of its cavity with a side screw.

Here’s how this socket works.

- Step 1: Put the socket on top of any bolt you want to tighten/remove

- Step 2: Adjust the size of its cavity by tightening the side screw

- Step 3: Make sure the bolt is snug inside the cavity

- Step 4: Put your wrench on top of the socket and rotate it

Shortcomings of Go2 sockets

While using the GO2 socket, you may notice that its spinning axis is anything but circular or symmetrical. Instead, this socket rotates along an asymmetrical axis, which means that it moves to one side as you’re turning the wrench to tighten/loosen the bolt (step 4). Here’s how this might pose an issue.

As you’re turning the wrench to remove the bolt, the socket will veer towards the outer side. If the bolt is in a tight spot (surrounded by other objects), the socket’s asymmetrical motion will cause its side-screw to come into contact with a nearby object, thereby posing a clearance problem.

This problem is worth a mention for another reason. The size of the socket itself might be too big for using it in a tight spot. Together with the above-mentioned clearance problem – its relatively large size for a socket makes the Go2 an unwanted choice for tight spaces.

Socket adapter

Socket adapters let you use the same socket for a variety of tasks. They allow you to adapt your socket’s drive size for use with a wrench of different drive sizes and types. For instance, a socket adapter will let you adjust a 1/4″ square drive socket for use with a ratchet having a 3/8″ square drive.

They contain two parts – male and female – and are available in a variety of types. Adapters don’t come in a one-size-fits-all category too. Read on to know more about their multiple types and decide which might come in handy for you.

Square drive adapter

Available in three types – standard, convertible, and electrical-insulating – the square drive adapters do exactly what their name implies. All of them convert sockets from one square size to another. Though the convertible and electrical-insulating types go one step ahead.

While convertible adapters require you to push your square drive through the adapter to change its size, the electrical-insulating adapters are, well, insulated. They protect the socket against unwanted contact with live electrical circuits. Here’s an example of how all these adapters work.

Assume for a moment that you have a 3/8″ drive ratchet and a 1/4″ drive socket. What you want here is a device that would let you use the former with the latter. And that’s precisely what you’d get with the 3/8″ to 1/4″ square drive adapter.

Note: While you can always go 1 size up (or 1 size down) with these adapters, going more in either direction will put your socket and ratchet at risk.

Pass-thru adapter

The Pass-thru adapters convert a pass-thru ratchet into a standard ratchet, thereby letting you use it with all your standard sockets. Some of them come with a push-button quick release and chrome finish.

One thing you must keep in mind – pass-thru adapter won’s turn your pass-thru ratchet exactly 100% into a regular one. The adapter may not stay fixed in the ratchet or even pop out when you apply too much torque.

Socket bit hex-shank adapter

Do you use drill/drivers or impact drivers? Then you might find socket bit Hex-shank adapters handy. These adapters fit the square drive socket to the hex drive on your drill/driver. And they do so to let you convert an impact driver into an impact wrench.

Some of them can also convert a standard drill into a quick-change drill bit, thereby saving you from using two drills or from the laborious task of repetitive chuck tightening and loosening. But their fancy working mechanism doesn’t mean they are expensive. These adapters are cheap.

U-joint adapter

Ever hunched under the hood of newly-made cars? Then you may have noticed how cramped everything is in there. It’s almost impossible for your standard socket – or wrench – to get in there and get things done. Which is why you need a U-joint adapter.

These adapters are incredibly flexible and can go all around. They are also available in multiple drive sizes – 1/4″, 3/8″, 1/2″, and even 3/4″. Most of them are chrome plated and can therefore last forever, as long as you don’t deliberately mishandle them.

Just remember that these sockets also suffer from a shortcoming. Their flexibility makes them lose their torque, almost as much as upwards of 20 percent. So you may not want to use them with the calibrated torque wrench.

Hand tool or impact tool?

We have already made it clear in one of the previous sections that regular sockets are for hand tools and impact tools are for impact sockets and how you can distinguish between both. The same advice goes for adapters. If you use impact tools, impact adapters are suitable. Here’s why.

In stark contrast to standard adapters, impact adapters have a sturdy design that can withstand each impact’s shock, thereby preventing the likelihood of cracks and breaks and extending the socket’s and the adapter’s life.

Aside from that, impact adapters help provide a snug fit to powered tools. This allows them to save the tool’s square drive from unusual deformation or damages. On the contrary, if you insist on using a regular adapter with an impact tool, the risk of ruptures will be very high.

Socket extension: Treatment for hard-to-reach bolts

Here’s everything you need to know about socket extensions:

Why should you have them?

Also known as ‘extender arms,’ socket extensions attach to a socket on one end and a ratchet on the other. This allows them to extend the socket’s length, thereby making it easier for you to access nuts and bolts that are hard-to-reach.

Extensions typically range ½ inches (15mm) to 20 inches (510mm) in length and are available in 1-inch (25mm) to 3-inch (75mm) increments. You can also attach different extensions to increase their length even further. They provide an added grip with a knurled section as well.

Pros

- Increase the length of the socket

- Provide grip with a knurled section

- Give access to hard-to-reach nuts and bolts

Cons

- Might make the whole setup – extension + socket -a little bulky

- Lose torque

What features do you need?

While standard socket extensions will get the job done in most cases, you may need something special in rare cases. But what is that something special? It depends on your answers to the below-mentioned questions.

How hard-to-reach are the bolt’s angles?

Do you find it difficult to see them from outside? Feel that your standard socket extension won’t be able to access them? Then you may need either a wobble socket extension or a flexible socket extension. Here’s why we’re saying that.

Wobble socket extensions are designed to let the socket move a little. They allow you to hold the socket at an angle and are available in two types:

- Wobble

- Wobble plus: if you press the socket in further, it becomes a straight extension.

Flexible socket extensions boast a flexible shaft that allows them to be bent into multiple positions. This makes it possible for them to access hard-to-reach areas with ease.

Is electrical shock your concern?

Then you’d do well with electrical-insulating socket extensions. These extensions are insulated with a rubber coating that won’t let electricity pass through. The rubber coating, therefore, protects both the extension and the socket against accidental contact with live electrical circuits.

Provided you are going to buy one of these, make sure it meets IEC 900 Standard or ASTM F1505-01 Standards. Both these certifications are awarded only to those hand tools that display extreme electrical insulating properties in laboratory conditions.

Do you work at a flammable place?

In that case, you may need non-sparking socket extensions. Mostly made of aluminum bronze, such extensions meet OSHA requirements that ratify non-sparking tools for places where combustible residues and flammable vapors are present.

Hand tool or impact tool?

Provided you’re using an impact tool, we recommend that you use an impact extension with it. That’s because impact socket extensions have a heavy-duty design that allows them to withstand the shock of each impact, without giving way to cracks or ruptures that may develop if you decide to use an impact tool with a standard socket extension.

Best socket sets review

Best socket sets for the money

Neiko 02440A 3/8″ drive impact socket set

Pros

- Comes with a sturdy case

- Laser-etched markings on the sockets

- Black phosphate coating protects sockets from dirt and oil deposits

Cons

- Only offers a 30-day returns guarantee

- Laser-etched markings are prone to wearing off quickly

- Cr-V material is not for heavy-duty tasks

The Neiko 02440A offers multiple deep and shallow impact sockets, 3″ and 6″ extension bars, a u-joint adapter. The manufacturer also provides a 1/2″ to 3/8″ reducer, which is very useful if you have a 1/2” drive ratchet. All of them are made of heat-treated chromium-vanadium (Cr-V) and can thus rust corrosion and pretty high torque.

Equally noteworthy is this model’s heavy-duty case. It boasts a blow-molded design and features two lever locks to ensure the safety of its contents. The case also has socket size labels to make organizing its contents a cinch for its users.

You might find it useful to note that all sockets feature a 6-point design coated with black phosphate. The former makes sure that they don’t round off corners. The black phosphate coating, meanwhile, protects the sockets from dirt, oil, and grease.

Not everything about this socket set is hunky-dory, though. An impact socket is made of Cr-V? Nah, it is not really “impact” since Cr-V is more brittle and easy to shatter when it comes to impact tools. So wear safety glasses if you use them with an impact driver or wrench.

Besides, the laser-etched markings are prone to wearing quickly and therefore won’t last that long. Its users are also furious with the case’s plastic hinge – which they think could break down in the face of abuse.

Verdict: The Neiko 02440A is easily one of the most affordable impact socket sets on the market. It is suitable for those looking to perform light-duty work around the house or in the garage. But its shortcomings mentioned above restrict its utility for heavy-duty work.

EPAuto ST-003-1 1/4” & 3/8” drive socket set

Pros

- Offers 72 teeth ratchet

- Chrome resistant sockets

- Sturdy case

Cons

- Markings are difficult to see

The Neiko Drive impact socket set comes with multiple sizes of 6-point and a few small 8-point sockets, one 3/8″ reversible ratchet, and one spin disk. All of them are made from hardened treated chrome vanadium steel alloy and can therefore last for ages as long as you use them for occasional work around the house.

Equally notable is the 72 tooth ratchet that is included in this set. It offers a 3/8” drive size (which is very useful around the house) – and a quick-release button that allows it to get on/off the sockets easily. Though you can’t expect it to perform high-torque tasks as ratchets with 1/2” drive size or fewer teeth do.

Then comes this model’s plastic case. You might find it useful to note that the case’s hinges and latches are well-made and can withstand abuse. Its interior is equally excellent as it makes sure that things remain in place when the case is being shaken from outside.

One thing which we didn’t like about this set was the visibility of its markings. They are difficult to see and had to be done over with a black felt tip to become visible in low light conditions.

Verdict: The EP Auto 1/4” and 3/8” drive socket set is one of those models whose price tag won’t blow a hole in your pocket. But as the availability of a 72-tooth ratchet in this set shows, it has cut no corners to keep its asking price low.

Neiko 02446A 1/2″ drive impact socket set.

Pros

- Corrosion-resistant finish

- Heavy-duty case

- Made of premium chrome vanadium steel

Cons

- Ratchet isn’t simply strong enough

- Cr-V material is not for heavy-duty tasks

The Neiko 02446A provides multiple 1/2” drive sockets, three 1/2” drive extension bars, one 3/8” to 1/2” drive impact adaptor, among other things. All of them have laser etching, which will start to fade with rough use in the long run. The absence of an 18mm socket in the set might also bother some users. Instead, the set includes a 3/4” socket, which is quite close to 18mm, but a bit loose.

Nothing will bother you about its case though. It is easy to close for moving around without forcing you to lock its clasps. There’s a foam cushion on top of the case, preventing the case’s contents from rattling.

Yet another thing we liked about the case was the size labels. They help you organize your storage and make sure you can get whatever you’re looking for without investing too much time. And the fact that two lever locks protect the entire structure means everything inside the case will remain safe.

The only major issue we had with this model was with the sturdiness of its ratchet. If there is any load on the bolt that you’re trying to tighten or loosen, the ratchet won’t be able to do anything apart from breaking down as its internal gear isn’t strong enough to handle heavy-duty tasks.

And again, brittle Cr-V will not stand with impact tools in the long term.

Verdict: Despite its high-asking price, the Neiko 02446A ½” drive impact socket set is only useful for tasks around the house. That’s mainly because the lack of sturdiness of its ratchet limits this set’s utility for rugged and heavy-duty usage.

DEWALT DWMT73804 socket set

Pros

- Hard stamped markings on pieces

- Extra room in the case for spare tools

- Comes with a lifetime warranty

- 72-tooth ratchet for access in tight spaces

Cons

- Has nothing to stop its contents from rattling on a road journey

The DeWalt socket set offers basic SAE and metric sizes of 1/4” and 3/8” drive sockets (sizes that cover all the needs in your house), one 3/8” drive drill adapter, a quick-release ratchet, and one 3/8” to 1/4” drive adapter. It’s nice to have for emergency or home usage but might be a little light for you if you’re a ‘tools’ person.

DeWalt counted on hard stamped markings to make different socket sizes recognizable. We liked them because, compared to laser-etched markings, they are less susceptible to wear and tear over time. That means even with rough uses, the markings will stay intact for years to come.

Its rock-solid construction isn’t the only thing that impressed us about this model’s case. What caught us by surprise was that in every row, there is room for extra bits. You can exploit this space to store spares or house bits that aren’t included in the set. However, some customers find this feature makes the case larger than needed. It’s up to you!

While the case doesn’t have a foam insert – which is why things might rattle quite a bit when you’re driving with it in the back of your vehicle. Though the pieces will still stay in their designated place, the case will hold up well to abuse. And if it didn’t, you can always take advantage of this set’s lifetime warranty.

Final Verdict: Looking to get your hands on a socket set for home uses? Then the DeWalt Socket set with its lifetime warranty and the rock-solid case is a must-have for you.

TEKTON 1/4” drive 6-point socket & ratchet set

Pros

- Comes with a lifetime warranty

- Wear-resistant die-stamped markings

- Space for extra tools

Cons

- Lack of knurling on the sockets

- Case does not have a handle

The TekTon 1/4” drive 6-point socket and ratchet set comes with every size from 4 to 14mm and 5/32 to 9/16 inch in both standard and deep lengths. All its sockets feature a 6-point design that allows them to apply force to the fasteners’ flat sides, not the corners. This keeps rounding-off at bay.

The sockets are well-made with their chrome-plated finish, but there’s one thing about them that bothered us. They don’t have any knurling and can therefore be difficult to hold for those of you with greasy or oily fingers. However, they do have die-stamped markings to make their sizes easy to read.

Especially noteworthy is the 90-teeth ratchet that comes in this set. It has a quick-release button and a minimum swing arc of 4 degrees. Having said that, the ratchet has a slightly lower maximum torque and is intended for confined space and fine-tuning work.

While most other socket sets come with living hinges, the hinges on this set’s case have a metal pin, making it more durable. It has also left a huge vacant space on its bottom left side to store other tools. However, the case does not come with a handle, which is sometimes inconvenient.

Verdict: The Tekton 1/4” drive 6-point socket and ratchet set comes with a lifetime guarantee and has large die-stamped size markings that aren’t easy to wear off also includes a 90-tooth ratchet suitable for confined space work. At an affordable price, this set is a “bang for the buck” if you are DIYers. What more can you ask for!

Best socket sets for mechanics

DEWALT DWMT81535 mechanics tool set

Pros

- Greater contact with fasteners

- Offers a huge variety of sockets

- Backed by a lifetime warranty

Cons

- Case is too compact to provide space for spare tools

- Socket markings could have been better

This excellent collection of 62 sockets, each boasting chrome polish, marries a wide range of SAE, deep-SAE, metric, and deep metric sockets with performance and affordability. But the absence of an attachment adapter for a drill/impact driver for the largest sockets still leaves something to be desired.

Also on offer are 72-tooth ratchets. Their finer teeth give a minimum swing arc of 5 degrees and thus provides excellent access in tight spaces. Both the sockets and the wrenches incorporate DirectTorque Technology that makes tightening/loosening easy by allowing for greater contact with fasteners.

The fact that some of the socket sizes are duplicated comes across as a double-edged sword. On the one end, it’s a plus point as you will always have a spare in case the socket gets lost. However, if you’re too meticulous with your tools and never let them get lost, the duplicate sizes may sit there useless.

All of them are housed inside a durable blow-molded case. It is made of high-quality plastic and has metal latches to keep your tools safe and secure. The case is incredibly compact and makes sure things stay where they are when being shaken – but it also prevents the case from offering space to spares.

Verdict: The DEWALT DWMT81535 mechanics tool set is perfect for the professional technician seeking to add to their beloved but worn-out tools – or the DIY auto mechanic who might simply be looking for an upgrade.

DEWALT DWMT75049 mechanics tool set

Pros

- Full set no skips for basic to slightly advanced tasks

- Hard stamped markings

- Durable and sturdy case

- Extra space for extra tools

- Good selection of Torx and Allen socket

Cons

- Quality control issue

- Spots designed to hold the sockets are too tight

The DeWalt DWMT75049 set includes sockets of multiple sizes and types, 1/4”’, 3/8”, and 1/2” drive 72-tooth ratchets, extension bars, adapters, and more! All regular sockets are 6-point – a big bonus! Dewalt also wisely picks the right Torx and Allen socket sizes to best meet your uses. Overall, it’s a little overkill for DIYers since this set can cover all the basic needs in your garage and even some advanced work.

The sockets also have deep laser etched markings for easy identification, though the markings will get worn out over time. Meanwhile, the 72-tooth ratchet has a low-profile lever that allows for one-hand operation while also reducing catch points. This makes it a must-have for work in tight spaces. On the other hand, the ratchet’s fat design handle is a bonus for high torque application.

Then there is the case. It is made of sturdy blow-molded plastic and can therefore test heavy abuse without breaking a sweat. Hinges and latches are also well made. One more bonus for the case is extra space for your spare tools.

There are a few areas in which this toolset could have done better. Quality control is a worrying issue some customers have encountered. A limited lifetime warranty will solve this problem. However, if you live far from a big city, the warranty policy may incur more time and cost.

The spots designed to hold the sockets take their job very seriously, making it extremely difficult to pull out the socket. You may even need to pry them out using a screwdriver.

One more thing you should notice is the whole set is pretty heavy. But I think it is inevitable when you go for mechanic socket sets.

Verdict: The DeWalt DWMT75049 set comes with all socket sizes, a 72-tooth ratchet, and a limited lifetime warranty. Throw into the mix its sturdy blow molded case, and this set becomes a must-have for both DIY as well as professional mechanics.

Crescent CTK170CMP2 mechanics tool set

Pros

- Affordable

- Cover all of mechanics’ basic needs

- Hard stamped markings

- Durable and sturdy case

Cons

- Plastic, flimsy hinges

- Laser markings fade over time

The Crescent General Purpose tool set contains tools needed for most of the mechanics’ basic needs. It offers 1/4”, 3/8”, and 1/2” drive sockets (SAE and Metric) and ratchets, and other crucial accessories. However, the set only includes one 3/8” to 1/2” adapter, which sometimes is not enough for customers’ needs.

Crescent has used laser engraving to mark the tools. The only shortcoming of this decision is that laser engraving, as we all know, tends to lose its shine over time. It’s also difficult to identify the marking in low lighting conditions. Crescent, therefore, could have done a lot better here.

You can say the same about the case. Users complain that its hinges are plastic and feel flimsy, and we tend to agree with them. Though it can still keep things steady when they are shaken and allows sockets to be snapped in and out of their designated spots with ease.

One can have no complaints about the lifetime warranty, though. Crescent has included no fine-print in the warranty documentation to prevent users with genuine complaints from taking advantage of the warranty and getting the faulty tools or the entire set repaired/replaced.

The biggest bonus of this set is the price. Compared to the value you get, this set offers you possibly the best price on the market. However, “the best” is always subjective. Do you need a set for garage tasks and house works? “The best” is the right word for you! If you need something more advanced, Nah!

Verdict: The Crescent CTK170CMP2 is one of those toolsets that come in handy for any project in your garage. With its collection of 170 sockets, ratchets, wrenches, pliers, and more, this is undoubtedly one of the best choices for your wallet.

Craftsman 450-piece mechanic’s tool set

Pros

- Multiples of some common bits

- Hard stamped markings

- 16 common wrenches sizes

- Extra room on top for more tools

Cons

- Ratchet not for tight space

- Not-so-much sturdy case

- Doesn’s include 10mm and 19 mm wrenches

The Craftsman 450-piece mechanic’s tool set offers 191 sockets (6-point, 8-point, 12-point), three quick-release ratchets (1/4”, 3/8” and 1/2” drives), and much much more. All of them feature laser-engraved markings which will wear out with time or with heavy-duty uses.

Each of the three ratchets feature a 45-teeth design and are therefore suitable for tasks requiring high torque. But they aren’t any good for delicate or confined space work as their relatively larger minimum swing arc.

Craftsman has come up with a solution to this problem. It has provided this set with 16 combination wrenches that would slip in where the ratchers won’t go. These are not a wide selection of wrenches (especially, this set excludes very common 10mm and 19mm wrenches). Other than that, these wrenches can cover a majority of your regular tasks. The US-based manufacturer has also provided the set with duplicated common bits thereby letting you pick a spare in case you lose the original one.

Its case is made of plastic with designated strong snaps to keep everything secure. That’s where the case’s good features end. It feels flimsy and is nowhere near sturdy enough to hold 450 pieces. Sure, you can keep it going if you take particular care of it. But don’t count on its weak hinges and poor-quality material of construction to withstand years of mishandling

Verdict: In the light of the above-mentioned features, the audience that this set is meant to serve are crystal clear. They include amateurs doing light duty work or DIYers performing auto repair tasks.

WORKPRO W003056A 450-piece mechanics tool set

Pros

- Limited lifetime warranty

- Heavy-duty yet compact case

- Neat organization of tools

- Extra room on top for more tools

Cons

- Doesn’t include an actual screwdriver

- Warranty doesn’t cover all parts and situations

- Ratchet not for tight space

The WorkPro 450-piece mechanics tool set features three quick-release ratchets, multiple variants of 1/4”, 3/8”, and 1/2” drive sockets, six extension bars, four adapters, and much more! All the pieces are made of heat-resistant chrome vanadium steel and come with chrome-plated markings.

That this set comes with 45-tooth ratchets – with an 8-degree minimum arc swing – comes across as a double-edged sword. On the one end, the lower number of teeth enables the ratchet to withstand a huge application of force without breaking down.

We were impressed with this set’s case. It is made of blow-molded plastic and features four tiers to let you organize your tools. The case provides extra space for your spares tools and boasts four latches to secure your components. Each of the three lower trays has its own locks too. You can thus count on the case to keep your tools secure and withstand the weight you place on the plastic handle to carry the set.

You should note that this toolset offers a “limited” lifetime warranty. That means that the manufacturer will replace only those parts or pieces that are mentioned in the warranty book and break down in normal usage. Others that are mishandled by the consumer or not covered under the warranty won’t be replaced.

Verdict: The WorkPro 450-piece mechanics tool set places greater emphasis on sockets and ratchets than most other tool sets, thereby becoming a must-have for those of you who regularly work on projects with innumerable amounts of nuts and bolts of different sizes.

Conclusion

Sockets are available in multiple sizes, types, and lengths. You can also categorize them based on their contact points and the application they’re designed for. They allow you to take their utility to the next level using adapters and extensions – both of which we have discussed in this article.

On top of that, we have also presented you with the reviews of the best socket sets money can buy. Now the mission is on you to use the information provided above to select the socket set that best meets your requirements. Good luck!